Menu

|

|

Background

A heat exchanger is a device in which energy is transferred from one fluid to another across a solid surface.

Exchanger analysis and design therefore involve both convection and conduction. Radiative transfer between the exchanger

and the environment can usually be neglected unless the exchanger is uninsulated and its external surfaces are very hot.

Two important problems in heat exchanger analysis are (1) rating existing heat exchangers and (ii) sizing

heat exchangers for a particular application. Rating involves determination of the rate of heat transfer,

the change in temperature of the two fluids, and the pressure drop across the heat exchanger. Sizing involves

selection of a specific heat exchanger from those currently available or determining the dimensions for the

design of a new heat exchanger, given the required rate of heat transfer and allowable pressure drop. The LMTD

method can be readily used when the inlet and outlet temperatures of both the hot and cold fluids are known.

When the outlet temperatures are not known, the LMTD can only be used in an iterative scheme. In this case the

-NTU method can be used to simplify the analysis. -NTU method can be used to simplify the analysis.

Energy Considerations:

The first Law of Thermodynamics, in rate form, applied to a control volume (CV), can be expressed as

where  stands for mass-flow rate (e.g., 1bm/min or kg/min) crossing the CV boundaries, h is

specific

enthalpy (energy/mass), stands for mass-flow rate (e.g., 1bm/min or kg/min) crossing the CV boundaries, h is

specific

enthalpy (energy/mass),  surr is the rate of heat transfer from the CV to its surroundings, and surr is the rate of heat transfer from the CV to its surroundings, and

st is the rate of change of energy stored in the CV. This simplified form of the First Law assumes

no work- producing processes, no energy generation inside the CV, and negligible kinetic and potential energy in the fluid

streams entering and leaving the CV. In steady state operation the energy residing in the CV is constant, meaning that st is the rate of change of energy stored in the CV. This simplified form of the First Law assumes

no work- producing processes, no energy generation inside the CV, and negligible kinetic and potential energy in the fluid

streams entering and leaving the CV. In steady state operation the energy residing in the CV is constant, meaning that

st =0.

If, furthermore, the boundary of the CV is adiabatic (i.e., perfectly insulated), then st =0.

If, furthermore, the boundary of the CV is adiabatic (i.e., perfectly insulated), then  surr =0. Under these circumstances

Eq. (1) reduces to a simple balance of enthalpy inflow and enthalpy outflow: surr =0. Under these circumstances

Eq. (1) reduces to a simple balance of enthalpy inflow and enthalpy outflow:

Applied to a heat exchanger with two streams passing through it, Eq. (2) can be rearranged to give:

h(hh,i-hh,o) = h(hh,i-hh,o) =

c(hc,o-hc,i)

(3) c(hc,o-hc,i)

(3)

where the subscripts h and c indicate the hot and cold fluids, respectively, and i and o indicate inlet and

outlet conditions. In words, Eq. (3) says that the rate of energy loss by the hot fluid (left-hand side) equals

the rate of energy gain by the cold fluid.

Shell and Tube Heat Exchanger

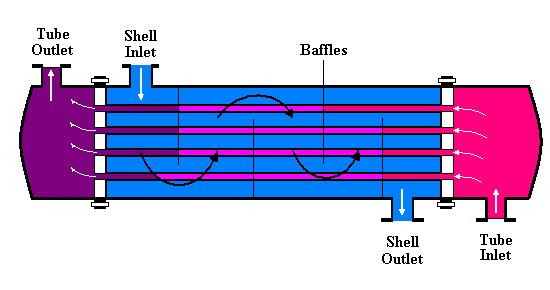

Figure 1 is a schematic diagram of a shell-and-tube heat exchanger with one shell pass and one tube pass.

The cross-counterflow mode of operation is indicated.

Figure 1. Shell-and-tube-heat exchanger with one shell pass and one tube pass; cross- counterflow operation.

Inside the heat exchanger the hot and cold fluid temperature distributions would have the form sketched in Fig. 2(a).

Figure 2. (a) Temperature distributions in a counterflow heat exchanger.

Figure 2. (b) Energy balance in a differential length element.

The points 1 and 2 on the x axis represent the two ends of the heat exchanger. Provided there is no energy

loss to the environment and that the exchanger has reached steady state, then dq, the rate of heat transfer from

the hot fluid, is exactly equal to the rate of heat transfer to the cold fluid in a differential length dx of the exchanger

surface. For the special case of fluids that are not changing phase and have constant specific heats

dp = - h Cp,h dTh =

- Ch dTh' &

(4) h Cp,h dTh =

- Ch dTh' &

(4)

dp =  c Cp,c dTc =

Cc dTc'

(5) c Cp,c dTc =

Cc dTc'

(5)

where Ch and C care called the hot and cold fluid heat-capacity rates, respectively.

Integration of Eqs (4) and (5) along the heat exchanger (from 1 to 2) gives

q = Ch(Th,i-Th,o)

(6)

and

q = Cc(Tc,o-Tc,i)

(7)

1. Logarithmic Mean Temperature Difference (LMTD) Method

The differential heat-transfer rate dq across the surface area element dA can also be expressed as

dq = U TdA,

(8) TdA,

(8)

where is the local temperature difference between the hot and cold

fluids and U is the overall coefficient of heat transfer at dA. Both U and T vary with position inside the heat exchanger (i.e., x), but by combining Eqs (4) and (5) with Eq. (8) it is

possible for a single

pass exchanger to integrate over the exchanger contact surface from inlet to out. The result of the integration is

T vary with position inside the heat exchanger (i.e., x), but by combining Eqs (4) and (5) with Eq. (8) it is

possible for a single

pass exchanger to integrate over the exchanger contact surface from inlet to out. The result of the integration is

q = AUm  Tln'

(9) Tln'

(9)

where q is the total heat-transfer rate (BTU/min), A is the total internal contact area

(ft2), Um is the mean overall coefficient of heat transfer (BTU/min ft2º F), defined as

and is the logarithmic mean temperature difference (LMTD), given by

As shown in Fig. 2(a), T1 = T h,i-Tc,o and T1 = T h,i-Tc,o and  T2 = Th,o-T c,i

for the counterflow, single pass case. Equation (9) is also applied to more complicated heat-exchanger designs

with multipass and cross- flow arrangements with a correction factor applied to the LMTD. See Ozisik (1).

As mentioned above, if both inlet and outlet temperatures are specified the LMTD can be calculated from

Eq. (11) and q from either Eq. (6) or Eq. (7). Then the product is given explicitly by Eq. (9). Further

specification of then "sizes" the heat exchanger, i.e., determines A and the dimensions of the internal flow passages. T2 = Th,o-T c,i

for the counterflow, single pass case. Equation (9) is also applied to more complicated heat-exchanger designs

with multipass and cross- flow arrangements with a correction factor applied to the LMTD. See Ozisik (1).

As mentioned above, if both inlet and outlet temperatures are specified the LMTD can be calculated from

Eq. (11) and q from either Eq. (6) or Eq. (7). Then the product is given explicitly by Eq. (9). Further

specification of then "sizes" the heat exchanger, i.e., determines A and the dimensions of the internal flow passages.

2.  -NTU Method -NTU Method

In cases where only the inlet temperatures of the hot and cold fluids are known, the LMTD cannot be

calculated beforehand and application of the LMTD method requires an iterative approach. The recommended

approach is the effectiveness or  -NTU method. The heat-exchanger effectiveness, -NTU method. The heat-exchanger effectiveness,

, is defined by , is defined by

= q/qmax,

(12) = q/qmax,

(12)

where q is the actual rate of heat transfer from the hot to cold fluid, and qmax

represents the maximum possible rate of heat transfer, which is given by the relation

qmax = Cmin(Th,i-Tc,i)

(13)

where Cmin is the smaller of the two heat capacity rates (see above, Eqs (4) and (5).

Thus, the actual heat transfer rate can be expressed as

q =  Cmin(Th,i-Tc,i)

(14) Cmin(Th,i-Tc,i)

(14)

and calculated, given the heat-exchanger effectiveness  , the

mass-flow rates and specific heats of the two fluids and the inlet temperatures. , the

mass-flow rates and specific heats of the two fluids and the inlet temperatures.

The value of  depends on the heat-exchanger geometry and flow pattern

(parallel flow, counterflow, cross flow, etc.). Theoretical relations for depends on the heat-exchanger geometry and flow pattern

(parallel flow, counterflow, cross flow, etc.). Theoretical relations for  and graphical characteristics are given by Ozisik (1) and Incropera & DeWitt (2) for a limited selection

of heat-exchanger types. For a single pass counterflow exchanger like the one used in this exercise

and graphical characteristics are given by Ozisik (1) and Incropera & DeWitt (2) for a limited selection

of heat-exchanger types. For a single pass counterflow exchanger like the one used in this exercise

where C Cmin / Cmax and N Cmin / Cmax and N UmA / Cmin. The dimensionless factor is known as the number of transfer units.

It is an indicator of the actual heat-transfer area or physical size of the exchanger. An experimental determination

of effectiveness is found by

UmA / Cmin. The dimensionless factor is known as the number of transfer units.

It is an indicator of the actual heat-transfer area or physical size of the exchanger. An experimental determination

of effectiveness is found by

|