Panzerfaust

WW II German Infantry Anti-Tank Weapons

Page 5: Machine Guns

Maschinengewehr

The first weapon available to the infantry to have a limited

effect against armor is the machine gun. Machine guns derive their limited

armor-penetrating capability both from the single bullet's penetration

ability and from the effect the repeated hits of bullets in quick succession

- as is the case with a machine gun - onto the same spot have on thin steel

plates. The metal's structural integrity suffers and eventually tends to

break from material fatigue. Therefore, to judge the penetrating power

of machine guns the determining factors are:

- penetrating power of the ammunition used (depending on the V0

the weapon achieves with the ammunition),

- theoretical and practical rate of fire and

- accuracy / density of the hit group

(the hits need to be concentrated on a small area to achieve the effect

described above).

Infanteriepatrone 7,9mm / Mauser

7.92x57 amunition

This

cartridge was used by the german Mauser Karabiner 98K, Gewehr 41, 43 and

numerous other rifles as well as in aircraft, vehicle and infantry machine

guns. As the german standard rifle cartridge

This

cartridge was used by the german Mauser Karabiner 98K, Gewehr 41, 43 and

numerous other rifles as well as in aircraft, vehicle and infantry machine

guns. As the german standard rifle cartridge it was called Infanteriepatrone 7,9mm ("infantry cartridge"),

also known as the 7,9mm - Militärpatrone ("military cartridge")

or as Mauser - Standardmunition 7,92x 57 (Mauser as the weapon company

that introduced the ammo for its famous 98K rifle; 7.92mm is the calibre

and 57mm the length of the casing (not the chamber as in the US); also,

in germany a bore's caliber is measured from land to land). The total production

of this cartridge during WW II was 10,475 million (that is over ten billion).

Sometimes, esp. among angloamericans, it is also referred to as 8 mm

Mauser.

it was called Infanteriepatrone 7,9mm ("infantry cartridge"),

also known as the 7,9mm - Militärpatrone ("military cartridge")

or as Mauser - Standardmunition 7,92x 57 (Mauser as the weapon company

that introduced the ammo for its famous 98K rifle; 7.92mm is the calibre

and 57mm the length of the casing (not the chamber as in the US); also,

in germany a bore's caliber is measured from land to land). The total production

of this cartridge during WW II was 10,475 million (that is over ten billion).

Sometimes, esp. among angloamericans, it is also referred to as 8 mm

Mauser.

The fired projectile of the Infanteriepatrone had a typical initial energy

E0 of 3,700 Joule (sS - projectile of 12.8g

at a V0 of 760m/s) but could reach initial energies

of over 4,500 Joule (some V-Patronen) depending on the concrete

ammunition type and firing weapon.

Between 80 and 90 % of all 7,9mm ammunition produced was of the 7,9

sS (sS for schweres Spitzgeschoss = "heavy pointed bullet")

type; the complete cartridge weighed 27g, it was 80.6 mm long and contained

2.7g of gunpowder; the projectile weighed 12.8 g and was 35mm long. When

fired from a MG34 or MG42 (as well as from the other rifles using the cartridge)

it had a typical V0 of 755 m/s. The regular sS

projectile had the following penetration performance: 85cm of dry pine

wood at 100m, 65cm at 400m, 45cm at 800m and 10cm at 1,800m; 10mm of iron

at 300m, 7mm at 550m; 5mm of steel at 100m; 3mm at 600m.

The second most used type was the SmK (Spitzgeschoss mit Kern

= "pointed bullet with core") bullet that measured 37.2mm, weighed

11.5 g and contained a hardened steel core (about 8% of all produced 7.9mm

rounds).

Another

type was the SmK L'spur (L'spur = Leuchtspur = "bright trace"

= "tracer") bullet that was the previous type combined with a

tracer that burned for 800 to 900 m (a little less numerous than the SmK).

In the picture at right a soldier is seen preparing a 7.92mm ammunition

belt for a machine gun (presumably adding tracers at every seventh round).

Another

type was the SmK L'spur (L'spur = Leuchtspur = "bright trace"

= "tracer") bullet that was the previous type combined with a

tracer that burned for 800 to 900 m (a little less numerous than the SmK).

In the picture at right a soldier is seen preparing a 7.92mm ammunition

belt for a machine gun (presumably adding tracers at every seventh round).

The lS (leichtes Spitzgeschoss = "light pointed bullet")

which had an aluminum core and therefore weighed only 5.5g which resulted

in a higher speed of V0 = 925 m/s but of course also

in a shortened total range (the bullet was used mainly in the air defense

role; about 4-7% of the total production), the lS-L'Spur which with

a length of 37.2mm and a weight of 6.1g was again the tracer version of

the lS (less than 1% of total production).

A version produced mainly for use with the MG 17 as

aircraft armament was the so-called V-Patrone which had an increased

powder charge that increased the V0 by 15%. This ammunition

type was available with the PmK projectile ("Phosphor mit Stahlkern"

= "phosphor with steel core") or with the B ("Beobachtung"

= "Observation") projectile contained a little phosphor

and exploded upon impact, the latter ammunition type was also known as

the B-Patrone and was used as an incendiary round; both types are

not counted in the 7,9mm production

.

The final and most interesting (for our purposes) bullet type was the SmK(H).

The H stood for Hartkern (hardened core), this was the armor piercing

version of the 7,9mm Infanteriepatrone. The projectile had a length

of only 28.2mm, weighed 12.5 g and contained a tungsten core that was 22.5

mm long. The propellant gunpowder of the shell was increased to 3.6 g.

The bullet had a penetration power of almost 20mm of plain steel at a range

of 500m (90° impact angle). However, production of this ammunition

type ceased in March 1942 because of an acute shortage of tungsten; still,

SmK(H) cartridges continued to be issued to the troops as late as

February 1943. while it was still inproduction, this ammo type accounted

for 1 to 2 % of the production of 7,9mm Infanteriepatronen.

When the machine guns used the normal sS ammunition they achieved

an armor penetration of up to 10mm and more at close ranges. Now, on to

the machine guns themselves. Development of the german machine guns went

towards a general purpose machine gun, therewith abandoning the differentiation

hitherto between light machine guns carried around by the assaulting infantry

and heavy machine guns that were intended as stationary support weapons.

First developments in this direction were the MG 29 and the MG

30. The latter was not accepted by the german armed forces but by the

austrian army; therefore, after austria became part of the third reich,

the Wehrmacht eventually had this weapon too. It was also produced during

WW II in a small production run for the finnish forces. Another development

by the companies Mauser and Metallwarenfabrik Kreuzlingen led to the LMG

32 that formed the basis for the MG 34.

Maschinengewehr 34 ( MG34, MG. 34

)

Development

of the Maschinengewehr 34 ("machine rifle") was officially

credited to the chief engineer Louis Stange of the company Rheinmetall

in Sömmerda, although most of the development work had been done by

Heinrich Vollmer from the company Mauser

Development

of the Maschinengewehr 34 ("machine rifle") was officially

credited to the chief engineer Louis Stange of the company Rheinmetall

in Sömmerda, although most of the development work had been done by

Heinrich Vollmer from the company Mauser Werke in Oberndorf by including details from the LMG 32, the MG

Dreyse 13 and the Solothurn MG 30 weapons. It was

a very good weapon in terms of quality. However, although the MG 34 was

a considerable improvement over the WW I - type weapons (the famous 08/15

machine guns of WW I consisted of 383 single pieces!) this quality in design

and finish also made for a comparably slow production and a high price

of 327.-- RM per weapon; also, 49 kg of raw material were used to machine

the parts from. Although a brilliant design - the weapon immediately was

agreed upon as the standart machine gun -, the precision machined parts

proved to be very sensitive and prone to malfunction in the harsh conditions

of field use. The reload mechanism depended on the recoil forces, the weapon

had two triggers, one for single (the upper trigger part) and one for automatic

fire (the lower trigger part).

Werke in Oberndorf by including details from the LMG 32, the MG

Dreyse 13 and the Solothurn MG 30 weapons. It was

a very good weapon in terms of quality. However, although the MG 34 was

a considerable improvement over the WW I - type weapons (the famous 08/15

machine guns of WW I consisted of 383 single pieces!) this quality in design

and finish also made for a comparably slow production and a high price

of 327.-- RM per weapon; also, 49 kg of raw material were used to machine

the parts from. Although a brilliant design - the weapon immediately was

agreed upon as the standart machine gun -, the precision machined parts

proved to be very sensitive and prone to malfunction in the harsh conditions

of field use. The reload mechanism depended on the recoil forces, the weapon

had two triggers, one for single (the upper trigger part) and one for automatic

fire (the lower trigger part).

The MG 34 could use both magazine-fed and belt-fed ammunition (the

above-mentioned 7.92mm standard infantry ammuntion). Available were Doppeltrommel

("double drum") saddle drum magazines of 75 rounds and gegurtete

Munition ("linked/belted ammunition") belts of 50 rounds

(weight: 1.5 kg) and 250 rounds (boxed; weight of a filled 250-round belt

box: 8.35 kg). The single belts of course could be connected to make an

endless belt.In the role as a light machine gun with bipod the weapon often

was used with 50-round Gurttrommel, a small drum magazine containing

the 50-round belt. To

prepare the weapon to fire the drum magazines - by default all later produced

models of the weapon were set to fire belted ammunition - the top cover

part of the casing housing the breech mechanism had to be changed to a

cover part that could accomodate the saddle magazine ammunition.

To

prepare the weapon to fire the drum magazines - by default all later produced

models of the weapon were set to fire belted ammunition - the top cover

part of the casing housing the breech mechanism had to be changed to a

cover part that could accomodate the saddle magazine ammunition.

As required by the specifications it was the first true general purpose

machine gun: with a bipod as a light machine gun it weighed 12.1 kg, mounted

on a tripod it was used as a medium machine gun; the small tripod weighed

6.75 kg, the large tripod (that at 400.-- RM was more expensive than the

weapon itself) weighed 23.6 kg. The barrel weighed 2kg, the bipod (which

cost 15,- RM) weighed 1kg.

The

MG34 was 122.5 cm long, the barrel was 60.0 cm long (other sources

62.5cm) and had a rifling of 4 grooves; as mentioned above, caliber was

7.92mm and the V0 of the bullets was 755 m/s; early

models could fire at a rate of either 600 or 1000 rounds per minute by

toggling a switch on the pistol grip; soon this was abandoned and most

models did not have this switch, the weapons were finished at the factory

set at a fixed rate between 800 and 900 rounds per minute. After first

experiences on the eastern front experiments with a MG 34 S called

version took place: with a shorter barrel of 50cm it achieved rates of

fire up to 1,700 rounds per minute; however, this drastically reduced reliability

and life expectancy of the weapon to a degree where this weapon was considered

unfeasible. Another, actually produced version was the MG34/41.

The weapon used many new parts, including the spring of the successor MG42,

to achieve it's rate of fire of 1,200 /min. Length of the MG34/41 was 112cm;

barrel length 56cm; 1,707 (other sources: 1,705) were built from February

to June (other sources: May) 1942.

The

MG34 was 122.5 cm long, the barrel was 60.0 cm long (other sources

62.5cm) and had a rifling of 4 grooves; as mentioned above, caliber was

7.92mm and the V0 of the bullets was 755 m/s; early

models could fire at a rate of either 600 or 1000 rounds per minute by

toggling a switch on the pistol grip; soon this was abandoned and most

models did not have this switch, the weapons were finished at the factory

set at a fixed rate between 800 and 900 rounds per minute. After first

experiences on the eastern front experiments with a MG 34 S called

version took place: with a shorter barrel of 50cm it achieved rates of

fire up to 1,700 rounds per minute; however, this drastically reduced reliability

and life expectancy of the weapon to a degree where this weapon was considered

unfeasible. Another, actually produced version was the MG34/41.

The weapon used many new parts, including the spring of the successor MG42,

to achieve it's rate of fire of 1,200 /min. Length of the MG34/41 was 112cm;

barrel length 56cm; 1,707 (other sources: 1,705) were built from February

to June (other sources: May) 1942.

Life expectancy of the barrel was 5,000 to 6,000 rounds provided that it

was changed according to manual. The MG 34 provided for a quick

change of barrel: The barrel was connected to the main body by a hinge

mechanism; to change the barrel, the body was simply swung to the side

and the barrel could be pulled out without having disassemble the breech

mechanism.  Because

of the sensitivity of the MG 34 for dirt and damages in field use, it was

preferred to still put this weapon into vehicles even after the MG 42 was

introduced and therefore free up the MG 42 for infantry use. The vehicle-mounted

version of the MG 34 was fitted with a schwerer Lauf ("heavy

barrel") or Panzerlauf ("armor barrel") that compensated

for the lesser change of barrel and the armored housing also protected

the barrel to a degree.

Because

of the sensitivity of the MG 34 for dirt and damages in field use, it was

preferred to still put this weapon into vehicles even after the MG 42 was

introduced and therefore free up the MG 42 for infantry use. The vehicle-mounted

version of the MG 34 was fitted with a schwerer Lauf ("heavy

barrel") or Panzerlauf ("armor barrel") that compensated

for the lesser change of barrel and the armored housing also protected

the barrel to a degree.

The MG 34 was produced until the end of the war and a total number

of 354,020 was built.

click here for additional color pictures

of the MG34.

Maschinengewehr 42 ( MG42, MG. 42 )

The

comparably complicated construction of the MG 34 restricted mass

production, therefore the numbers demanded by the army could never be met.

It was soon obvious that a simpler model was needed. The new machine

gun was to be manufactrured from pressed and punched steel parts. The proposed

construction of the company Metall- und Lackierwarenfabrik Johannes Grossfuss

AG in Döbeln looked promising from the very start. It's inventor was

a skilled labor by the name of Grunow who was specialized in the technique

of punching and pressing steel. He was sent into the regular training for

machine gunners in the army to find out what a machine gun's characteristics

were to be and then went on to design the MG 42. The MG 34 and the

MG 42 are easily discerned even at a quick glance by their barrel housings:

while the MG 34 has a round housing with many round cooling holes,

the MG 42 has a square housing with oval cooling openings at the

left and top side and a large cooling slit on the right side.

The

comparably complicated construction of the MG 34 restricted mass

production, therefore the numbers demanded by the army could never be met.

It was soon obvious that a simpler model was needed. The new machine

gun was to be manufactrured from pressed and punched steel parts. The proposed

construction of the company Metall- und Lackierwarenfabrik Johannes Grossfuss

AG in Döbeln looked promising from the very start. It's inventor was

a skilled labor by the name of Grunow who was specialized in the technique

of punching and pressing steel. He was sent into the regular training for

machine gunners in the army to find out what a machine gun's characteristics

were to be and then went on to design the MG 42. The MG 34 and the

MG 42 are easily discerned even at a quick glance by their barrel housings:

while the MG 34 has a round housing with many round cooling holes,

the MG 42 has a square housing with oval cooling openings at the

left and top side and a large cooling slit on the right side.

The first prototype designated MG 39 was accepted for troop trials

in February 1939; it was refined into the the fifth and final prototype,

the MG39/41, and sent into a large combat evaluation involving 1,500

MG 39/41. After small detail improvements, mass production was started

and the weapon was introduced into the army as the MG 42. Total

production of the MG 42 for the german Wehrmacht during WW II was

414,964. The weapon was produced by the companies Mauser Werke AG in Berlin,

Gustloff-Werke in Suhl, Grossfuss in Döbeln, Magnet in Berlin and

Steyr-Daimler-Puch in Vienna.

The

weapon was air-cooled and recoil-operated with a slightly recoiling barrel;

the recoil mechanism based on a newly invented construction of a breech

with rollers. The belted mauser 7.92mm ammunition

was fed from the left.

The

weapon was air-cooled and recoil-operated with a slightly recoiling barrel;

the recoil mechanism based on a newly invented construction of a breech

with rollers. The belted mauser 7.92mm ammunition

was fed from the left.

The unmatched simplicity, functionality and effectiveness of the design

not only resulted in a an astonishing ruggedness and immunity to the conditions

of front use, it also decreased the amount of resources and raw material

necessary to produce one MG 42 to 27.5 kg; it took only 75 work hours to

complete a MG 42 as opposed to the 150 necessary for the MG 34; the MG

42 cost only 250.-- RM. Even today it is still regarded by many experts

as the best machine gun construction ever.

It had an overall length of 122.0 cm, a barrel of 53.0 cm and weighed 11.6

kg in the role as a light machine gun equipped with the bipod. Then bipod,

the same as on the Mg 34, could be mounted to the front or the center of

the gun. In the role as a heavy machine gun it utilised the newly developed

Lafette 42 ("mount") that weighed 20.5 kg. The MG42's

nominal rate of fire was 1500/min; reportedly, this rate varied to a degree

with individual weapons; furthermore, the rate slightly increased in prolonged

bursts. The higher rate of fire led to a decreased barrel expectancy when

compared with the MG34: the barrel was only good for between 3,500 to 4,000

rounds. Later,. barrels were chrome-plated which lengthened life expectancy

a bit; still, the barrel became hot rather fast and had to be changed often;

the MG42 accounted for this with an even further simplified barrel change

mechanism.

Because of the ruggedness of the MG 42, it was preferred to issue this

weapon to the infantry and rather use the MG 34 in vehicle mounts where

the MG 34 was less exposed to dirt and damage.

A krummer Lauf ("bent barrel") was tested that was bent

30° from the normal axis. Much like the krummer Lauf available for

use with the Sturmgewehr 44 it was intended

for firing from defilade, at street corners etc. Naturally, the krummer

Lauf wore out rather quick and the idea was deemed unfeasible for a machine

gun.

With the acute material shortages of 1944 it was deemed necessary to further

simplify to save resources. This resulted in the MG 45, also called

MG42V, which modified the breech mechanism of the MG42 so that it didn't

completely lock before firing. This increased the theoretical rate of fire

even further, the weapon now only weighed 9 kg and - most importantly -production

was simplified and needed only steel of minor quality. First tests were

undertaken in June 1944, but development dragged on and eventually only

ten were ever built.

click here for additional color pictures

of the MG42.

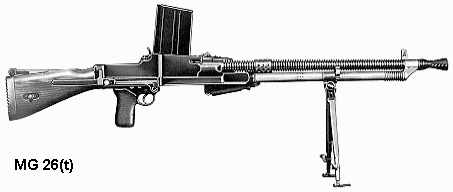

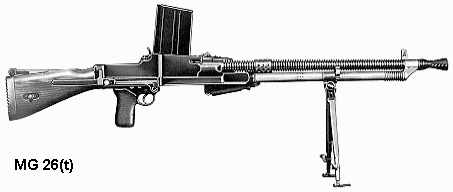

MG 26(t) / ZB 1926

MG 26(t) was the german designation for the czechoslovakian machine

gun ZB 1926. It was the product of the search of the czechoslovakian

military during the 1920ies for a light machine gun in the same class as

the american BAR from 1918. After a long and tedious process over several

years that included several weapon trials and competitions, decisions and

retaking of decisions, the choice eventually fell upon the Praga 1924,

a light machine gun developed by A. Marek, Podrabski and the brothers Václav

and Emanuel Holek, at the end of 1924. Originally devised as a belt-fed

weapon, it was only accepted after having been redesigned to be magazine-fed.

Because the state company that was to produce the weapon was busy producing

Mauser 98 rifles in license for the czech military, the production start

for the machine gun was delayed. In the meantime the weapon was improved

by V. Holek, and eventually it production started at the czech weapon company

Zbrojovka Brno in Brno with the assistance of Skoda. The redesigned weapon

was introduced into the czech military at the end of 1926 and received

the designation Light Machine Gun Model ZB 1926. The weapon was

to become one of the most successful czechoslovakian weapon designs; besides

the ones built for the own military, about 38,500 were exported to several

countries.

When germany occupied czechoslovakia in march 1939, the ZB 1926 was

incorporated into the german army under the designation MG 26(t),

the suffix (t) denominating a captured weapon of czech ("tschechisch")

origin. Together, the germans aquired 31,204 machine guns of the types

ZB 1926 and it's successor, the ZB 1930. Another

source for these weapons were those captured in Yugoslavia that had originally

bought 1,500 ZB 1926, although it is unknown how many of these exactly

were captured by the germans.

The MG 26(t) is an air-cooled, gas-pressure operated fixed-barrel

machine gun. The necessary gas pressure is taken from a little hole drilled

into the barrel near the muzzle and activates a gas piston that opens and

moves the breech block, the empty cartridge case is ejected. The loading

of a new cartridge and the locking of the breech in the firing position

is then done via a strong recoil spring. Although the weapon is viewed

by many experts as one of the light machine gun designs, it has the distinct

flaw of a too small amount of ammunition because of the use of magazines

which only contained 20 rounds.

The weapon by design had always been in the german caliber 7.92mm

Mauser; it can be fired both in semi- and full-automatic mode. The

weapon used straight or curved magazines inserted from the top that weighed

0.8kg when fully loaded with 20 rounds; the sights of the weapon ranges

from 200m to 1,500m in increments of 100m.Other data: Length 116.5cm, barrel

length 60cm, rate of fire 520/min, weight 8.9kg (empty = without ammunition),

V0 = 760 m/s.

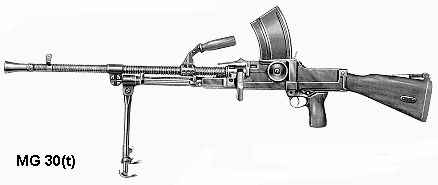

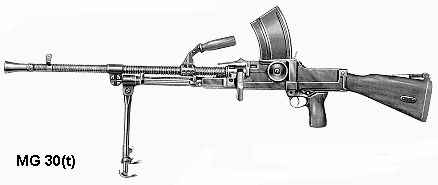

MG 30(t) / ZB 1930

MG

30(t) is the german designation for the czechoslovakian ZB 1930

light machine gun. During the production of the ZB 1926

the weapon had been continously improved in different aspects, an intermediate

model was called ZB 1927. This development eventually resulted in

the improved ZB 1930 model, the most visible change being the relocation

of the gas-pressure vent away from the muzzle to a position roughly halfway

of the barrel. There was also an export version that was changed to be

more tolerant to accept a wider range of ammunitions of differing manufacturing

quality under the designation ZB 1930 J.

MG

30(t) is the german designation for the czechoslovakian ZB 1930

light machine gun. During the production of the ZB 1926

the weapon had been continously improved in different aspects, an intermediate

model was called ZB 1927. This development eventually resulted in

the improved ZB 1930 model, the most visible change being the relocation

of the gas-pressure vent away from the muzzle to a position roughly halfway

of the barrel. There was also an export version that was changed to be

more tolerant to accept a wider range of ammunitions of differing manufacturing

quality under the designation ZB 1930 J.

A major customer of this latter model was Yugoslavia with 15,500 weapons

bought. Other major international customers of the ZB 1930 were Romania

with 17,131 ( a later ally of germany on the eastern front in WW II) and

turkey with 9,805 of these machine guns. It should also be noted that this

weapon was the basis of the ZGB 1933 that became widely known as

the british Bren light machine gun. Weapons of the type ZB 1926

or ZB 1930 also were sometimes called ZB-machineguns or Holek-machineguns

after their inventor.

With the occupation of czechoslovakia in 1939 the germans captured 31,204

machine guns of the types ZB 1926 and ZB 1930, mostly

the latter. From these, 1,500 were sold to Bulgaria. The ZB 1930

was integrated into german army service under the designation MG 30(t).

Production of the weapon was continued under german occupation for the

german forces: 10,430 were produced for the SS. In 1941 production was

switched over to the german MG 34 and production of

the MG 30(t) / ZB 1930 ceased.

The MG 30(t) had the same basic layout as its predecessor, the MG

26(t). Caliber was still 7.92mm Mauser. The

range of the sights was increased to 2,000m. The weapon used straight or

curved 20-round magazines. Other data: Length 117cm,  barrel

length 60cm, weight (empty) 9.65kg, rate of fire 600/min, V0

= 760 m/s.

barrel

length 60cm, weight (empty) 9.65kg, rate of fire 600/min, V0

= 760 m/s.

The picture at right shows what appears to be an MG 30(t) in an improvised

AA role.

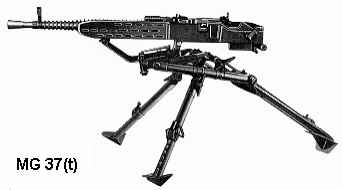

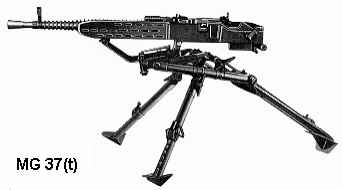

MG 37(t) / ZB 1937

The MG 37(t) was another originally czechoslovakian design; this

heavy machine gun originally carried the designation ZB 1937. It

was the answer to the already failed quest of the czech military during

the 1920ies for a heavy machine gun. In early 1930 Václav Holek

and Miloslav Rolcik started development of a heavy machine gun that after

several modifications resulted in the heavy machine gun ZB 1935

that showed itself vastly superior to the WW I - era Schwarzlose machine

guns then still in use.

The weapon was built in a limited series and also bought by Great Britain,

which manufactured it under license by BSA Ltd and under the designation

BESA machine gun for use as a vehicle-mounted machinegun for

tanks. An intersting fact is that because the BESA was identical

to the czech origin, both were in the 7.92mm Mauser

caliber. Because the british armor wanted the BESA, but the BESA could

not be converted to fire the british .303 ammunition, and because the infantry

did not want to switch over all their Enfields to the german caliber, the

tankers were granted an exception and even had their own special manufacturing

plant in england for producing the german ammunition type.

Of the czech ZB 1935 287 were sold to romania; the weapon was further

improved and standardized as the heavy mg for the czech military under

the designation ZB 1937. Few weapons had been built before the germans

occupied czechoslovakia, most of which were exported to other countries,

e.g. romania bought another 8,000 ZB 1937. About 12,000 were built

by the czech weapon company in Brno for international custiomers and another

6,000 for the czech military.

The weapon was integrated into german army use under the designation MG

37(t) and production was continued until 1942, when production was

switched over to producing parts for german weapon designs. Until then,

another 6,411 weapons had been built for the SS.

The MG 37(t) is air-cooled and gas pressure - operated; when firing

the barrel (together with the locked breech block) is recoiling about 2cm,

then the bullet passes the gas valve and the gas pressure unlocks the breech

from the barrel for the further recoil. The weapon is belt-fed with metal

ammunition belts feeding 7.92mm Mauser ammunition

from the right side. The ammunition belts by default came in 100-round

(weighing 3.4kg) and 200-round (weighing 6.8 kg) lengths but could be linked

endlessly.

A light and a heavy barrel were available, the heavy barrel is recognizable

by the distinctive cooling gills around the barrel. The weapon had a regulator

for the amount of extracted gas pressure from the gas valve on the barrel.

The rate of fire could be increased by the switch of a special accelerator

from 500 to 700 rounds per minute.

A distinct disadvantage of this weapon was the tedious procedure when changing

the barrel. The sights range from 200 to 2,500 meters. Other data: length

109.5cm, barrel length 73cm, weight (empty) 19kg, weight (empty with tripod)

36.5kg, V0 = 790 m/s.

Maschinengewehr Solothurn 1930 /

MG 30

This

weapon was designed by Louis Schmeisser of the company Rheinische Metallwaren-

und Maschinenfabrik (Rheinmetall) in its branch in Sömmerda. The development

of machine guns was prohibited for germany under the Versailles treaty.

Therefore, Rheinmetall cooperated with companies in switzerland and austria.

Originally rejected by the Reichswehr, germany's army during the Weimar

republic era, the wepon was introduced as the standard machine gun in switzerland

as Maschinengewehr Solothurn S2-100 and S2-200 (Solothurn

was the swiss company that license-built the weapons) and in austria as

Maschinengewehr Modell 1930. The latter weapons were built by Steyr-Daimler-Puch

AG. After austria became part of the third reich in march 1938, these weapons

of the austrian army eventually found their way into the german army under

the designation Maschinengewehr Solothurn 1930 or simply MG 30

(sources indicate a number in the range of about 10,000 weapons). Rheinmetall

used this weapon as a basis for developing the Flugzeug-Maschinengewehr

MG 15 and MG 17 ("aircraft machine gun") for germany's Luftwaffe

aircraft.

This

weapon was designed by Louis Schmeisser of the company Rheinische Metallwaren-

und Maschinenfabrik (Rheinmetall) in its branch in Sömmerda. The development

of machine guns was prohibited for germany under the Versailles treaty.

Therefore, Rheinmetall cooperated with companies in switzerland and austria.

Originally rejected by the Reichswehr, germany's army during the Weimar

republic era, the wepon was introduced as the standard machine gun in switzerland

as Maschinengewehr Solothurn S2-100 and S2-200 (Solothurn

was the swiss company that license-built the weapons) and in austria as

Maschinengewehr Modell 1930. The latter weapons were built by Steyr-Daimler-Puch

AG. After austria became part of the third reich in march 1938, these weapons

of the austrian army eventually found their way into the german army under

the designation Maschinengewehr Solothurn 1930 or simply MG 30

(sources indicate a number in the range of about 10,000 weapons). Rheinmetall

used this weapon as a basis for developing the Flugzeug-Maschinengewehr

MG 15 and MG 17 ("aircraft machine gun") for germany's Luftwaffe

aircraft.

The MG 30 is an air-cooled recoil-operated weapon with slightly

recoiling barrel. Ammunition is fed from a slightly curved 30-round magazine

inserted in the left side of the wepon. The machine gun can be fired both

in semiautomatic and full automatic mode depending on how much the trigger

is pulled by the gunner. The sights can be adjusted from 100m to 2000m

range. The weapon by default has a folding bipod attached two thirds down

the barrel. Barrel change reportedly is uncomplicated.

Technical data: Length 117cm, barrel length 60.0 cm; weight (empty) 9.5kg

(other sources: 7.7 kg); V0 = 760 m/s, rate of fire

800/min (other sources: 600/min). Ammunition: 30-round curved magazine

with 7.92mm Mauser cartridges.

Maschinengewehr Dreyse 13

In search of a new light, air-cooled machine gun the german military

ordered Louis Stange of Rheinmetall in Sömmerda to re-work the heavy

WW I watercooled Dreyse MG 1912. After some experimental prototypes the

weapon Maschinengewehr Modell Dreyse Gerät 13 was eventually

introduced by the Reichswehr in 1930 and production went to the company

Simson & Co. in Suhl which was the only company officially licensed

by the Versailles treaty to build automatic weapons in a limited number.

The weapon was officially phased out of service in 1934, but a small number

remained as reserve weapons. With the acute shortage of the Wehrmacht in

WW II regarding machine guns these reserve weapons (as well as the still

remaining MG 08 and MG08/15)

again had to be issued for service and reportedly the small number (no

more than a few thousand) was used all through the war.

The Maschinengewehr Dreyse 13 was an air-cooled recoil-operated

machine gun with slightly recoiling barrel. The weapon has a double trigger

with the upper part used for firing the weapon in single-shot mode and

the lower trigger used for full automatic; no linked ammunition belts could

be used: the standard 7.92mm ammunition is fed either

from special 25-round box magazines or from special 75-round double-drum

magazines attached to the left side of the breech. The sights could be

adjusted from from 100m to 2000m in 100m-increments. The weapon was regularly

fitted with a bipod. A Modell 13 k (K for "kurz" = "short")

version with a shortened barrel of 60cm and a Modell 13 kd ("kurz,

Dauerfeuer" = "short, prolonged fire") version with a shortened

and thicker barrel for firing prolonged on full automatic existed, but

the main infantry version was the regular Modell 13: technical data:

length: 134cm; barrel length 71.8cm; weight (empty with bipod) 11kg; weight

25-round magazine (empty) 390g; system rate of fire 550/min.

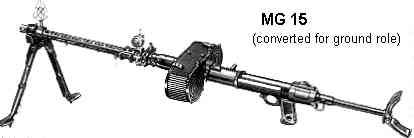

MG 15 / MG 17

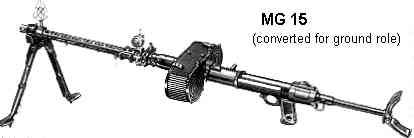

Based

on the system of the Rheinmetall MG 30 - design, the

Flugzeugmaschinengewehr MG 15 and MG 17 were the standard

aircraft machine guns equipping most german combat aircraft at the start

of WW II. The MG 15 was developed by Rheinmetall in Borsig as a

flexible-mounted defense machine gun for bomber aircraft, while the same

company's MG 17 was developed in 1936 as the fixed forward-firing

armament for fighter aircraft such as the Messerschmidt Bf 109E. An easy

recognition feature for differentiation bewteen the two types was that

the barrel housing of the MG 15 had many oval cooling slits while

the MG 17 had many round cooling holes. The MG 17 was suitable

for installing a synchronization device for shooting through the aircraft's

own propellor. Both weapons are air-cooled and recoil-operated; the MG

15 was magazine fed from Doppeltrommel double-drum magazines containing

75 rounds, the MG 17 was belt-fed, both used the standard machine

gun ammunition, the Mauser 7.92mm.

Based

on the system of the Rheinmetall MG 30 - design, the

Flugzeugmaschinengewehr MG 15 and MG 17 were the standard

aircraft machine guns equipping most german combat aircraft at the start

of WW II. The MG 15 was developed by Rheinmetall in Borsig as a

flexible-mounted defense machine gun for bomber aircraft, while the same

company's MG 17 was developed in 1936 as the fixed forward-firing

armament for fighter aircraft such as the Messerschmidt Bf 109E. An easy

recognition feature for differentiation bewteen the two types was that

the barrel housing of the MG 15 had many oval cooling slits while

the MG 17 had many round cooling holes. The MG 17 was suitable

for installing a synchronization device for shooting through the aircraft's

own propellor. Both weapons are air-cooled and recoil-operated; the MG

15 was magazine fed from Doppeltrommel double-drum magazines containing

75 rounds, the MG 17 was belt-fed, both used the standard machine

gun ammunition, the Mauser 7.92mm.

When

later in the war the Luftwaffe ("air weapon" - german air force)

no longer needed it's 7.9mm aircraft machine guns (7.9mm was considered

obsolete as aircraft armament and the smallest caliber guns were henceforth

13 and 15mm machine guns) they were given to ground troops, mainly the

field units of the Luftwaffe, because the german ground forces suffered

from a shortage of machine guns since production of the MG 34 and MG 42

could never meet the demand. Reworking the aircraft machine guns for the

ground role began no later than 1942 and involved new sights, a shoulder

rest, provision for mounting the weapon on the standard MG - tripods or

a bipod, spent cartridge deflector and carrying sling. Official number

of MG 15 was 17,648 and of MG 17 was 24,271 on 1.7.1944;

it is unknown how many of these had been already converted to ground use.

When

later in the war the Luftwaffe ("air weapon" - german air force)

no longer needed it's 7.9mm aircraft machine guns (7.9mm was considered

obsolete as aircraft armament and the smallest caliber guns were henceforth

13 and 15mm machine guns) they were given to ground troops, mainly the

field units of the Luftwaffe, because the german ground forces suffered

from a shortage of machine guns since production of the MG 34 and MG 42

could never meet the demand. Reworking the aircraft machine guns for the

ground role began no later than 1942 and involved new sights, a shoulder

rest, provision for mounting the weapon on the standard MG - tripods or

a bipod, spent cartridge deflector and carrying sling. Official number

of MG 15 was 17,648 and of MG 17 was 24,271 on 1.7.1944;

it is unknown how many of these had been already converted to ground use.

The MG 15 in the ground role had a length of 107.8 cm, weighed (with

bipod but w/o magazine) 11.5 kg (other sources 10.6kg), weight of 75-round

magazine (full) 4.3kg; barrel length 60.0 cm. It fired the standard 7.92x57

Mauser cartridge at a V0 of 755m/s. The MG

17 was 2kg heavier and fired at a rate of 1,200 rounds per minute.

MG 81

The

MG 81 was also originally an aircraft machine gun that was later

used in the ground role when it was no longer used for the Luftwaffe just

like the MG 15 and the MG 17 it

had replaced as aircraft machine gun. The weapon had been designed by the

Mauser Werke AG in Oberndorf and introduced in 1938, since early 1940 it

began replacing the MG 15 and MG 17 as the standard aircraft machine gun.

The major improvement in this new machine gun was a much higher rate of

fire and the flexibility of feeding the ammunition belt from either of

both sides. Often two machineguns were combined with a single trigger as

a twin machine gun under the designation MG81Z. Conversion of the

MG81 for the ground role included the addition of a bipod and a

shoulder pieces, either a steel piece that could be retracted or a wooden

pice. Many of the numerous twin MG81Z were used in the role of anti-aircraft

machine guns where they reportedly proved especially useful. More than

46,000 were built; of the 33,164 in use on 1.7.1944, 20378 were MG81Z,

the rest single-barrel MG81.

The

MG 81 was also originally an aircraft machine gun that was later

used in the ground role when it was no longer used for the Luftwaffe just

like the MG 15 and the MG 17 it

had replaced as aircraft machine gun. The weapon had been designed by the

Mauser Werke AG in Oberndorf and introduced in 1938, since early 1940 it

began replacing the MG 15 and MG 17 as the standard aircraft machine gun.

The major improvement in this new machine gun was a much higher rate of

fire and the flexibility of feeding the ammunition belt from either of

both sides. Often two machineguns were combined with a single trigger as

a twin machine gun under the designation MG81Z. Conversion of the

MG81 for the ground role included the addition of a bipod and a

shoulder pieces, either a steel piece that could be retracted or a wooden

pice. Many of the numerous twin MG81Z were used in the role of anti-aircraft

machine guns where they reportedly proved especially useful. More than

46,000 were built; of the 33,164 in use on 1.7.1944, 20378 were MG81Z,

the rest single-barrel MG81.

The MG 81 was an air-cooled, recoil-operated belt-fed (using the

standard ammo belts of the MG 34 and MG 42) 7.9mm machine gun weighing

only 8kg (empty, in the original aircraft version 6.5kg) (MG81Z:

12.9kg) and having a length of only 96.5cm; the short barrel length of

47.5 cm made for a slow V0 of only 705m/s (when using

standard 7,9mm Mauser ammo with sS projectile; with

the stronger V-Patrone it reached between 760 and

790m/s depending on projectile type); the high rate of fire of 1600/min

was not unproblematic for field use.

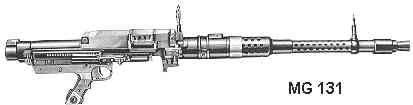

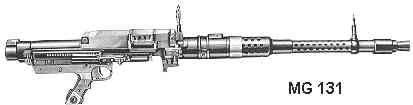

MG 131

After

of high relevance for this page are the other, heavy machine guns the Heer

("Army") received from the Luftwaffe.

After

of high relevance for this page are the other, heavy machine guns the Heer

("Army") received from the Luftwaffe.

The MG 131 was developed and manufactured by Rheinmetall, had a

caliber of 13mm, a length of116.8 cm and weighed 20.5 kg in the aircraft

role. The breech system of this air-cooled recoil-operated belt-fed weapon

was essentially an enlarged version of that used on the Solothurn

MG 30. For it's ground combat role it was modified by adding a bipod

and a shoulder piece. Barrel length was 55.0 cm. The original rate of fire

of 930/min was reduced for the ground role; it is unclear how many of the

144,124 of these weapons produced for the Luftwaffe aircraft were converted

for ground combat. They were reported to be reasonably effective against

lightly armored vehicles.

The belted ammunition used was the Patrone 13mmx64mm with either

an AP or a HE projectile fed in a metal-linked belt of 250 rounds (of course

belts could be linked for unlimited length).

The Panzerbrandgranaten - Patrone 13mm ("armor piercing incendiary

round - cartridge") had an AP projectile with a length of 51mm, weighed

38g and contained 0.4 g phosphor as incendiary which when fired from the

MG 131 had a V0 of 710m/s. The complete cartridge

measured 105mm overall, weighed 76g and had a propellant of 7.1g of gunpowder.

The Sprenggranaten - Patrone 13mm ("explosive round - cartridge")

was the HE ammo variant, it was 4g lighter, had the same powder charge

of 7.1g and reached a Vo of 750m/s.

MG 151

The heavy MG 151 was also originally an aircraft machine gun

that later was used in the ground role. The weapon, produced by the company

Mauser since 1940, in the version MG151/15 had a caliber of 15mm,

a length of 191.7 cm, a barrel length of 125.0 cm and weighed 41.5 kg,

which required the use of a small two-wheeled mount. The ammunition used

was the Panzergranaten-Patrone 15mm. It had a cartridge length of

147mm, weighed 165g, which includes the projectile that had a length of

67mm and weighed 72mm. The propellant of 24g of gunpowder made for a V0

of 850m/s, rate of fire was originally 700/min. the MG 151 was belt-fed.

Most of the MG 151 used in the ground role were used as air defense mounts.

Again, numbers of army-conversions are unclear, even total production of

the MG 151 15mm gun is hard to estimate since the production number of

249,609 includes a large majority of MG151/20, the 20mm version

of the same type (both weapons are completely idemntical apart from the

caliber) weapon rarely used in the ground role (but only in fixed AA emplacements).

Other Machine Guns

A number of other, less numerous / important types of machine

guns was employed by the german infantry during WW II, as there were 3,900

dutch Lewis-type M.20 machine guns were captured and used to defend the

channel islands under the designation MG 100(h) ("h" for

"holländisch" = "dutch"). Caliber 6.5mm, length

126.0 cm, barrel length 65.4 cm, weight 13 kg.V0 =

730 m/s, rate of fire 450/min, or a number of the captured british Bren

light machine guns roughly similar to the ZB 1930 /

MG 30(t) described above. The germans also still had a number of the

WW I - era watercooled MG 08 and LMG 08/15 machine guns in

service at the outbreak of WW II. The rather cumbersome weapons were not

very popular and were preferrably used in fixed emplacements such as in

the rear-area air defense role. They were of the Maxim pre-WW I system.

The russians also had a large number of these Maxim machine guns

in service in WW I which in turn were used again by the germans as they

captured these.

Previous Page : Production

Figures, Foreign Use Main

Page Next

Page : Tank Rifles

This

cartridge was used by the german Mauser Karabiner 98K, Gewehr 41, 43 and

numerous other rifles as well as in aircraft, vehicle and infantry machine

guns. As the german standard rifle cartridge

This

cartridge was used by the german Mauser Karabiner 98K, Gewehr 41, 43 and

numerous other rifles as well as in aircraft, vehicle and infantry machine

guns. As the german standard rifle cartridge it was called Infanteriepatrone 7,9mm ("infantry cartridge"),

also known as the 7,9mm - Militärpatrone ("military cartridge")

or as Mauser - Standardmunition 7,92x 57 (Mauser as the weapon company

that introduced the ammo for its famous 98K rifle; 7.92mm is the calibre

and 57mm the length of the casing (not the chamber as in the US); also,

in germany a bore's caliber is measured from land to land). The total production

of this cartridge during WW II was 10,475 million (that is over ten billion).

Sometimes, esp. among angloamericans, it is also referred to as 8 mm

Mauser.

it was called Infanteriepatrone 7,9mm ("infantry cartridge"),

also known as the 7,9mm - Militärpatrone ("military cartridge")

or as Mauser - Standardmunition 7,92x 57 (Mauser as the weapon company

that introduced the ammo for its famous 98K rifle; 7.92mm is the calibre

and 57mm the length of the casing (not the chamber as in the US); also,

in germany a bore's caliber is measured from land to land). The total production

of this cartridge during WW II was 10,475 million (that is over ten billion).

Sometimes, esp. among angloamericans, it is also referred to as 8 mm

Mauser. Another

type was the SmK L'spur (L'spur = Leuchtspur = "bright trace"

= "tracer") bullet that was the previous type combined with a

tracer that burned for 800 to 900 m (a little less numerous than the SmK).

In the picture at right a soldier is seen preparing a 7.92mm ammunition

belt for a machine gun (presumably adding tracers at every seventh round).

Another

type was the SmK L'spur (L'spur = Leuchtspur = "bright trace"

= "tracer") bullet that was the previous type combined with a

tracer that burned for 800 to 900 m (a little less numerous than the SmK).

In the picture at right a soldier is seen preparing a 7.92mm ammunition

belt for a machine gun (presumably adding tracers at every seventh round). Development

of the Maschinengewehr 34 ("machine rifle") was officially

credited to the chief engineer Louis Stange of the company Rheinmetall

in Sömmerda, although most of the development work had been done by

Heinrich Vollmer from the company Mauser

Development

of the Maschinengewehr 34 ("machine rifle") was officially

credited to the chief engineer Louis Stange of the company Rheinmetall

in Sömmerda, although most of the development work had been done by

Heinrich Vollmer from the company Mauser Werke in Oberndorf by including details from the LMG 32, the

Werke in Oberndorf by including details from the LMG 32, the  To

prepare the weapon to fire the drum magazines - by default all later produced

models of the weapon were set to fire belted ammunition - the top cover

part of the casing housing the breech mechanism had to be changed to a

cover part that could accomodate the saddle magazine ammunition.

To

prepare the weapon to fire the drum magazines - by default all later produced

models of the weapon were set to fire belted ammunition - the top cover

part of the casing housing the breech mechanism had to be changed to a

cover part that could accomodate the saddle magazine ammunition. The

MG34 was 122.5 cm long, the barrel was 60.0 cm long (other sources

62.5cm) and had a rifling of 4 grooves; as mentioned above, caliber was

7.92mm and the V0 of the bullets was 755 m/s; early

models could fire at a rate of either 600 or 1000 rounds per minute by

toggling a switch on the pistol grip; soon this was abandoned and most

models did not have this switch, the weapons were finished at the factory

set at a fixed rate between 800 and 900 rounds per minute. After first

experiences on the eastern front experiments with a MG 34 S called

version took place: with a shorter barrel of 50cm it achieved rates of

fire up to 1,700 rounds per minute; however, this drastically reduced reliability

and life expectancy of the weapon to a degree where this weapon was considered

unfeasible. Another, actually produced version was the MG34/41.

The weapon used many new parts, including the spring of the successor MG42,

to achieve it's rate of fire of 1,200 /min. Length of the MG34/41 was 112cm;

barrel length 56cm; 1,707 (other sources: 1,705) were built from February

to June (other sources: May) 1942.

The

MG34 was 122.5 cm long, the barrel was 60.0 cm long (other sources

62.5cm) and had a rifling of 4 grooves; as mentioned above, caliber was

7.92mm and the V0 of the bullets was 755 m/s; early

models could fire at a rate of either 600 or 1000 rounds per minute by

toggling a switch on the pistol grip; soon this was abandoned and most

models did not have this switch, the weapons were finished at the factory

set at a fixed rate between 800 and 900 rounds per minute. After first

experiences on the eastern front experiments with a MG 34 S called

version took place: with a shorter barrel of 50cm it achieved rates of

fire up to 1,700 rounds per minute; however, this drastically reduced reliability

and life expectancy of the weapon to a degree where this weapon was considered

unfeasible. Another, actually produced version was the MG34/41.

The weapon used many new parts, including the spring of the successor MG42,

to achieve it's rate of fire of 1,200 /min. Length of the MG34/41 was 112cm;

barrel length 56cm; 1,707 (other sources: 1,705) were built from February

to June (other sources: May) 1942. Because

of the sensitivity of the MG 34 for dirt and damages in field use, it was

preferred to still put this weapon into vehicles even after the MG 42 was

introduced and therefore free up the MG 42 for infantry use. The vehicle-mounted

version of the MG 34 was fitted with a schwerer Lauf ("heavy

barrel") or Panzerlauf ("armor barrel") that compensated

for the lesser change of barrel and the armored housing also protected

the barrel to a degree.

Because

of the sensitivity of the MG 34 for dirt and damages in field use, it was

preferred to still put this weapon into vehicles even after the MG 42 was

introduced and therefore free up the MG 42 for infantry use. The vehicle-mounted

version of the MG 34 was fitted with a schwerer Lauf ("heavy

barrel") or Panzerlauf ("armor barrel") that compensated

for the lesser change of barrel and the armored housing also protected

the barrel to a degree. The

comparably complicated construction of the MG 34 restricted mass

production, therefore the numbers demanded by the army could never be met.

It was soon obvious that a simpler model was needed. The new machine

gun was to be manufactrured from pressed and punched steel parts. The proposed

construction of the company Metall- und Lackierwarenfabrik Johannes Grossfuss

AG in Döbeln looked promising from the very start. It's inventor was

a skilled labor by the name of Grunow who was specialized in the technique

of punching and pressing steel. He was sent into the regular training for

machine gunners in the army to find out what a machine gun's characteristics

were to be and then went on to design the MG 42. The MG 34 and the

MG 42 are easily discerned even at a quick glance by their barrel housings:

while the MG 34 has a round housing with many round cooling holes,

the MG 42 has a square housing with oval cooling openings at the

left and top side and a large cooling slit on the right side.

The

comparably complicated construction of the MG 34 restricted mass

production, therefore the numbers demanded by the army could never be met.

It was soon obvious that a simpler model was needed. The new machine

gun was to be manufactrured from pressed and punched steel parts. The proposed

construction of the company Metall- und Lackierwarenfabrik Johannes Grossfuss

AG in Döbeln looked promising from the very start. It's inventor was

a skilled labor by the name of Grunow who was specialized in the technique

of punching and pressing steel. He was sent into the regular training for

machine gunners in the army to find out what a machine gun's characteristics

were to be and then went on to design the MG 42. The MG 34 and the

MG 42 are easily discerned even at a quick glance by their barrel housings:

while the MG 34 has a round housing with many round cooling holes,

the MG 42 has a square housing with oval cooling openings at the

left and top side and a large cooling slit on the right side. The

weapon was air-cooled and recoil-operated with a slightly recoiling barrel;

the recoil mechanism based on a newly invented construction of a breech

with rollers. The belted mauser

The

weapon was air-cooled and recoil-operated with a slightly recoiling barrel;

the recoil mechanism based on a newly invented construction of a breech

with rollers. The belted mauser

MG

30(t) is the german designation for the czechoslovakian ZB 1930

light machine gun. During the production of the

MG

30(t) is the german designation for the czechoslovakian ZB 1930

light machine gun. During the production of the  barrel

length 60cm, weight (empty) 9.65kg, rate of fire 600/min, V0

= 760 m/s.

barrel

length 60cm, weight (empty) 9.65kg, rate of fire 600/min, V0

= 760 m/s.

This

weapon was designed by Louis Schmeisser of the company Rheinische Metallwaren-

und Maschinenfabrik (Rheinmetall) in its branch in Sömmerda. The development

of machine guns was prohibited for germany under the Versailles treaty.

Therefore, Rheinmetall cooperated with companies in switzerland and austria.

Originally rejected by the Reichswehr, germany's army during the Weimar

republic era, the wepon was introduced as the standard machine gun in switzerland

as Maschinengewehr Solothurn S2-100 and S2-200 (Solothurn

was the swiss company that license-built the weapons) and in austria as

Maschinengewehr Modell 1930. The latter weapons were built by Steyr-Daimler-Puch

AG. After austria became part of the third reich in march 1938, these weapons

of the austrian army eventually found their way into the german army under

the designation Maschinengewehr Solothurn 1930 or simply MG 30

(sources indicate a number in the range of about 10,000 weapons). Rheinmetall

used this weapon as a basis for developing the

This

weapon was designed by Louis Schmeisser of the company Rheinische Metallwaren-

und Maschinenfabrik (Rheinmetall) in its branch in Sömmerda. The development

of machine guns was prohibited for germany under the Versailles treaty.

Therefore, Rheinmetall cooperated with companies in switzerland and austria.

Originally rejected by the Reichswehr, germany's army during the Weimar

republic era, the wepon was introduced as the standard machine gun in switzerland

as Maschinengewehr Solothurn S2-100 and S2-200 (Solothurn

was the swiss company that license-built the weapons) and in austria as

Maschinengewehr Modell 1930. The latter weapons were built by Steyr-Daimler-Puch

AG. After austria became part of the third reich in march 1938, these weapons

of the austrian army eventually found their way into the german army under

the designation Maschinengewehr Solothurn 1930 or simply MG 30

(sources indicate a number in the range of about 10,000 weapons). Rheinmetall

used this weapon as a basis for developing the  Based

on the system of the Rheinmetall

Based

on the system of the Rheinmetall  When

later in the war the Luftwaffe ("air weapon" - german air force)

no longer needed it's 7.9mm aircraft machine guns (7.9mm was considered

obsolete as aircraft armament and the smallest caliber guns were henceforth

13 and 15mm machine guns) they were given to ground troops, mainly the

field units of the Luftwaffe, because the german ground forces suffered

from a shortage of machine guns since production of the MG 34 and MG 42

could never meet the demand. Reworking the aircraft machine guns for the

ground role began no later than 1942 and involved new sights, a shoulder

rest, provision for mounting the weapon on the standard MG - tripods or

a bipod, spent cartridge deflector and carrying sling. Official number

of MG 15 was 17,648 and of MG 17 was 24,271 on 1.7.1944;

it is unknown how many of these had been already converted to ground use.

When

later in the war the Luftwaffe ("air weapon" - german air force)

no longer needed it's 7.9mm aircraft machine guns (7.9mm was considered

obsolete as aircraft armament and the smallest caliber guns were henceforth

13 and 15mm machine guns) they were given to ground troops, mainly the

field units of the Luftwaffe, because the german ground forces suffered

from a shortage of machine guns since production of the MG 34 and MG 42

could never meet the demand. Reworking the aircraft machine guns for the

ground role began no later than 1942 and involved new sights, a shoulder

rest, provision for mounting the weapon on the standard MG - tripods or

a bipod, spent cartridge deflector and carrying sling. Official number

of MG 15 was 17,648 and of MG 17 was 24,271 on 1.7.1944;

it is unknown how many of these had been already converted to ground use. The

MG 81 was also originally an aircraft machine gun that was later

used in the ground role when it was no longer used for the Luftwaffe just

like the

The

MG 81 was also originally an aircraft machine gun that was later

used in the ground role when it was no longer used for the Luftwaffe just

like the  After

of high relevance for this page are the other, heavy machine guns the Heer

("Army") received from the Luftwaffe.

After

of high relevance for this page are the other, heavy machine guns the Heer

("Army") received from the Luftwaffe.