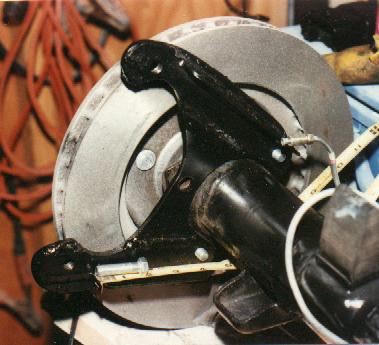

I mounted the rotor on the inside of the axle flange, this means removing

the wheel bearing and installing the rotor. You will have to get new wheel

mounting studs, re-drill your rotor to accept them, (if you drill to small

of a hole the rotor will crack when you press the studs in, if to large the

rotor may not spin true).

You can take the easy way out and mount the rotors on the outside of the axle flange, but you will loose 1/4" of wheel clearance, valuable space on a 55, especially when you have to change a tire! Temporarily mount your bracket on the axle flange (with rotor in position).

Install the brake pads in caliper and slide assembled unit over rotor. Slide the caliper down on rotor until you have an even amount of rotor showing (id and OD of rotor) on either side of the brake pads. This will give you an idea of where to drill your holes to mount your caliper to the flat stock you are working with. (I used air to lightly actuate the caliper and squeeze the rotor). You will note at this time that you might need to make spacers to mount the bracket to the axle flange because of a gap between the axle flange and mount. This you will have to measure, I just cut 3 square blocks to the proper size, drilled them, set them in place with the caliper, and tack welded them to the bracket while mounting them on a "dummy" housing.