Modernizing Cotton Belt - 1950 to Present

Dieselization of Motive Power

The introduction of the diesel-electric locomotive was a lifesaver for the rail industry, bringing with it revolutionary improvements in efficiency, economy and operating methods.

Diesel locomotives could start a heavy train from a standstill more quickly than a steam locomotive of the same horsepower, and could exert more pull at slow speeds. Moreover, diesels are ready to go to work at any time of the day or night. Between jobs they burn little or no fuel; they spend a great deal less time out of service than steam power, and shopping and repairs are radically less than the old power. In service they travel much longer distances without stopping for fuel and water.

First use of diesel power on the Cotton Belt was in 1942 when three 1000-horsepower switchers were purchased. Since that time more and more of these efficient power units have been added. By the end of 1953 the road was fully dieselized and all steam power had been disposed of or leased. Its rapid acquisition of diesel locomotives made the Cotton Belt one of the first railroads in the Southwest to be fully dieselized. In 1957 the Cotton Belt owned 134 diesel-electric units, including six "general purpose" locomotives purchased in that year. The major shop for making repairs to diesel locomotives was located at Pine Bluff, Arkansas, where a complete repair service was maintained. At other points only running repairs were made.

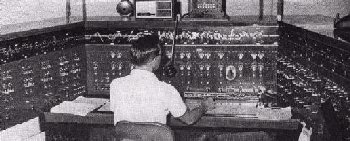

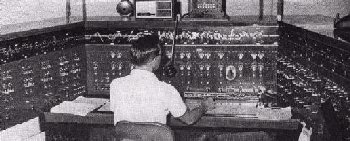

Centralized Traffic Control

The Cotton Belt, never a double-track road, realized that one of the most important factors in expediting trains, and thus giving better service, was the continuation of the centralized traffic control program inaugurated in 1941 but which had to be deferred during World War 2. Centralized traffic control was an electronic system of signals to control train movement. Train wheels acted as contacts in an electrical track circuit to actuate signals and indicated exact location of all trains. The electric impulses lit lamps on a track model board located in the dispatcher's office. Seated at his board in Pine Bluff, Arkansas, he can control train movements for hundreds of miles. By flipping levers and pushing buttons on the panel before him, the dispatcher Opens and closes railroad switches, shunts slow trains on to sidings, and expedites the meeting of trains running in opposite directions on the same track. With centralized traffic control a single-track railroad is able to handle up to 80 per cent more traffic with greater speed, efficiency and safety. In 1956 the Cotton Belt completed, at a total cost of $5 1/2 million, the program begun in 1941, and as of 1957 operated over 752 miles of signal-protected track from St. Louis, Missouri, to Corsicana, Texas.

Since this photo was taken, the Dispatcher was moved to Houston, Texas and converted to Computer control and now has been moved again to Denver, Colorado.

Pine Bluff Gravity Yard & Reference Photos

The most important yard change in the history of the Cotton Belt was in the process of taking shape in 1957 when the building of a modern electronic gravity yard was started at Pine Bluff, Arkansas, a central location on the railroad. The yard first opened in 1958. Trains are pulled out of the receiving tracks by Hump Engines ("Photo F") out past the Hump Tower on one of 2 Hump Leads toward the Arkansas River Bridge ("Photo E") and then are shoved over the hump at 2 miles-per-hour. Hump Engines are made up of 2 engines coupled at the Hood end for extra power needed to pull long trains over the Hump. Push-button controls in the Humpmaster's Tower (Photo "A") guide the cars through the labyrinth of automatic power switches to the desired classification tracks. As they roll, they will pass over an electronic computer which automatically determines various rollability factors such as weight, speed, wind and other weather conditions. The computer feeds this information to retarders or braking devices on the tracks which apply the necessary braking pressure to slow the cars down to a speed that will insure gentle coupling to other cars, thus avoiding damage to lading and equipment. The Retarder Operator (Photo "B"), who sits in a tower overlooking the bowl tracks, can take control of the retarders to aid the computer control.

Forty two classification tracks (#5 through #47) are provided with a total Capacity of about 50 cars each. In addition to the classification tracks, the new yard will contain rip track facilities for making repairs to 70 freight cars at a time and also contain two 56-car capacity track for cleaning cars. The local and storage yard has thirteen tracks with a capacity of 500 cars. There 15 receiving and departure tracks, (Main Line through #5 on the West side and #47 through #56 on the East side), each with a capacity of 140 cars.

Over two 140-car capacity lead tracks to the crest of the hump. The cars are cut off by the pin-puller ("Photo D") at the top of the crest & descend by gravity down the grade on their way to various classification tracks, where electronic equipment takes over. Trimmer Engines ("Photo C") at the south end of the yard pull the cars from the classification tracks and build the trains in the receiving tracks.

Gravity Yard - Retarder Tower on right

Photos from Pine Bluff Gravity Yard

Back to the  Roundhouse

Roundhouse

Back to the History of Cotton Belt

background Copyright © 1996, 1997, 1998 Wayne E. Beck

Feel free to copy

Photos (Pine Bluff) taken By Wayne Beck wbeck@email.com

08/15/98

This page hosted by

Get your own Free Home Page

Get your own Free Home Page

Roundhouse

Roundhouse