|

|

Components of the Tire/Wheel Assembly. Before we begin, it's probably wise to establish a common ground for describing the elements and dimensions of a tire. Refer to Figure 1.0, left, for descriptions I normally use. There are really only two major "physical" components to a tire assembly: the wheel itself, and the elastomeric material mounted to it that constitutes the tire. While sometimes used interchangeably, "wheel width"/"tire width" and "tire diameter"/"wheel diameter" are not necessarily the same dimension, nor, as we'll see later, are "tire width" and "contact |

|

|

width" or area. In those segments that discuss the condition of a relationship between the tire and wheel, each item is referred to individually. When the entire component is discussed, I, like everybody else, use the word "tire" generically, mostly because repeatedly typing "wheel/tire assembly" is a pain. Maybe. Unless I forget. |

||

| Some Observable Tire Conditions & Problems | ||

|

Looking at the length of this page, one might think that the simple act of buying a pair of drag tires subjects one to the risk of a great many problems. Uh, not really. Most manufacturers have acceptable production methods and quality control procedures, and ship out a decent product at a relatively reasonable price. As in all supply systems, however, sometimes "**** happens." So, in the following segments, let's examine some of the more noticeable conditions, or deviations from the "norm," that you might occasionally come across. We'll also look at how the various manufacturing techniques employed to produce a tire assembly can sometimes create these problems, and how they might have a significant effect on how and why the tire performs the way it does. So first, let's look for some of the more easily detectable conditions. |

||

|

|

Visible Sidewall Conditions. Based solely on what one can see, tires occasionally exhibit one (or more) conditions that relate to their position on and relationship to the wheel. Given the ideal configuration, "A", in Figure 1.1, left, where the tire material is precisely the same width as the wheel, and the sidewalls are perpendicular to the axle, you'll occasionally encounter a few manufacturing variations. "B" illustrates a tire ground "flat," but off set from the wheel. It's most common, at least on smaller diameter tires, to have an unsupported front surface with tires formed to the nominal width of the wheel, and somewhat rarer to see the back of the wheel uncovered. Given |

|

|

the way things work, I

suspect that such a back-offset condition is the result of cutting the

sidewalls, rather than grinding them. While a tire surface narrower

than the wheel that supports it isn't normally a problem (as evidenced

by radiused or beveled tread edges and tires where the sidewalls have

been tapered in - "negative" taper, narrowing into

the wheel - on purpose to narrow the tread contact patch), an

excessive amount of unsupported tire material can affect

performance. Figure 1.5, below, illustrates what can happen in those

circumstances. Yes and/or no, depending (and gosh, isn't that the clear answer you were looking for?). Yes, it's meaningful if it's excessive and can't be corrected, and no, it's not (absolutely) meaningful if it's minimal and/or it can be corrected. Follow me here a bit: given that this state is almost exclusively a condition of narrow-section tires, in the (appx.) .300" or narrower range, it's frequently the nature of the material of their construction, and not the manner of their construction, that creates this state. They bend, and sometimes they forget to unbend, and you have to remind them. Tires are made from a variety of soft, cellular elastomers and not solid aluminum or such, so remember that they frequently have less stabilized "memory" ability than other materials, and have an occasional tendency to remain near where they're offset (like a rubber band is great at remembering it's supposed to contract after you stretch it, but a little hazy on what exact attitude it's supposed to assume after it's relaxed). So? So try to accurately identify where on the wheel the tire offsets by slowly spinning it in a low-friction setup, e.g., axle ball bearings, and gently bend the body of the tire back towards the wheel until it goes away or at least diminishes to an acceptable level. Most slot drag cars are amazingly tolerant of some small degree of sidewall run out, and it would appear that there is a moderate amount of self-correction caused by centrifugal forces at work on the tire during a run. This is not, however, a circumstance where more is better. What I don't recommend is radical "electroshock therapy," wherein you chuck the sucker in your MotoTool and let 'er rip at several gajillion rpm. Yep, for a brief moment, the tire material will remember the way it was originally ground and attempt to return to that state. You won't notice that state because of the chunks of tire material zinging past you (or into you) while they whistle "Born Free." This is Tire Material/Adhesive Destructive Testing without the testing part. Don't. |

||

|

|

Circumference

Conditions.

I'll be honest with you: I've encountered some oddities in this area

that I can't figure out how to duplicate without seriously messing up

what I'm doing, and which really require someone, somewhere, to do

something absolutely stupid. Manufacturers don't stay in business for

long by repeatedly messing something up, so I have to write some of

these things off to, for want of a better term, "operator

error." Or, "Insufficient Mojo," depending. |

|

|

pretty interesting things to the tread surface, turning a tire while grinding the circumference invariably gives you a surface that is at least concentric with the turning center line. Cutting that same surface with a blade? A little more iffy, but usually almost self-correcting if you leave the cutting blade in its final trim position long enough. And then, at least for foam tires, there's the rare, misguided attempt at molding in place. It's what our friends the English refer to as "a snare and a delusion." Easy, quick and absolutely the best way to occasionally make what turns out to be a rubber "camshaft lobe" I can think of. Most tires are reasonably round. Including one pair of natural rubber tires I came across that had clearly been ground (and pretty well, at that), were perfectly round, at least as far as slot car drag tires go, and, oh, yes, were also mounted on a wheel that was .030" off center to the tire, an amount easily visible to the naked eye (I don't know how to do that while still using the correct diameter axle. Yet). Figure 1.2, above, shows another problem you might encounter on both natural rubber and foam tires, even those that have been ground to a circumference. To the best of my ability to observe, and given a tire which is as wide as the wheel that supports it, inadvertently creating an angled tread surface, both edges of which are still concentric to the turning center line, requires either a) some one/some thing to crank in an additional angle off a parallel to that center line for the grinding or cutting path, or b) a tool or grinding wheel/stone specifically shaped with that included angle on its surface. I discount the latter and figure that someone was watching the ball game during the manufacturing and pre-ship QA process. Interestingly, I've never seen more than one pair formed this way in any given "batch" of tires. There is, as it turns out, yet another way to achieve this same condition, and it's discussed in the material accompanying Figure 1.5, below. |

||

|

How to Create Other Tire Problems. Imagine! Finally, a topic where I actually have first-hand knowledge! Yep, a pile of ruined tires and a great deal of rubber and foam dust later, I now know exactly how to manufacture bad tires in an almost unbelievable number of ways. The good news is that I can also probably figure out how other people did them that way, too. In my opinion, the factors involved in creating most tire problems, at least during the manufacturing phase, are applied force - usually too much for unsupported tire material - and the manner in which the force is applied. To this you can occasionally add "speed," as in the speed at which the raw wheel/tire assembly is turned during sizing and finishing. These elements become critical due to the nature of the tire material. Either as a natural rubber compound (often referred to as "fish" rubber due to its odor), or a variety of cellular synthetic foams of various densities, these elastomers offer almost no meaningful resistance to applied force in the thicknesses and sections we deal with in slot car drag racing tires. Translation: when you push on them, they move, unless there's something behind them. When you push on them really hard, like when you're trying to cut them or grind them, they can sometimes do weird stuff you're not expecting. A common example of how these kind of materials react is the manner in which something like a gasket punch deals with differing materials. In a thin, semi-rigid gasket material, the punched hole is clean, and the material punched out is nearly uniform and cylindrical. In thicker, softer gasket material, however, despite the sharpness of the punch, the hole has a less-uniform wall, and the material removed frequently is significantly tapered, sometimes shaped in almost an hourglass form. Neat, huh? So, with some of these things in mind, let's go mess up some tires. |

||

|

When haste really can make

waste. Well, that's something of an exaggeration, as are the

illustrations, but not that much. Figure 1.3, left, shows some ways

in which force, excessively or improperly applied, can distort the

tire configuration. Example "A" shows a condition that can

occasionally be achieved by applying (primarily) grinding force to the

tire while moving the grinding surface in one direction while

not allowing the tire the time necessary to fully

"uncompress." Nor, for that matter, being smart enough to

also grind the tread in the other direction while I was at it,

essentially equalizing the distortion. It's a little bit harder to deform the actual tread surface, but not so hard that I haven't been able to occasionally accomplish it. |

|

|

|

||

|

Before I hit upon the

time/speed/force system and equipment I now use to make my own tires,

I could frequently manage to create a dished or "cupped"

tread surface by presuming that a preset stop on my tire machine would

offer the same ground dimension no matter what the time/speed/

material relationship actually was. Uh, no, not really. Figure 1.4.

above, shows, with some degree of exaggeration, what happens when you

try to hasten your tire manufacturing process by substituting, say, force

for time. And what, you ask, does time have to do with

this stuff? A last note, at least on this page, about do-it-yourself tire forming and reforming equipment: over the years, I've owned 5 dedicated tire-truing devices of one sort or another. Of those, 4 are gone, and only a compact, simple resurfacer remains for occasional use at the track. None could cut or grind tread widths or sidewalls worth a **** (this doesn't seem to be meaningful to out road-racing brethren), and if you think I'm going to use a mild steel pin to accurately cut a magnesium wheel with foam bonded to it, you may never have attempted to do it. I currently use a German bench lathe and two simple aluminum forms to grind the sidewalls (including the front of the wheel) and the tread surface with an assortment of adhesive-backed sandpaper. Equipment overkill used crudely, but it works just fine, albeit rather slowly, as you'll see on one of these pages sooner or later. |

||

|

|

||

| Some Less Obvious Conditions & Problems | ||

|

As they say on all those spiffy TV commercials (or at least, they used to), "But wait, there's more!" Beyond those conditions that you may be able to identify in the package, there are a few more areas where a little observation and inspection may save a great deal of frustration later on. In each of the following circumstances, I resolutely chased my mechanical "tail" off, looking for problems that clearly caused performance to suffer, but which escaped easy diagnosis (alternately, I was too dim to think clearly and connect what I saw to what I knew). Before you blame something else and/or drop kick that porker into the parking lot, make sure you're not encountering one or more of these conditions. You never know, right? Should you wonder, what follows is in no particular order of importance. |

||

|

"Roundness."

I lied. This part is important. Maybe most important,

which is why it occurred to me first, and I mentioned it earlier,

above, under "Circumference Problems." Besides, if I

started this Section with the words "Cylindrical &

Non-cylindrical Tire Characteristics," it'd be even more

confusing, and "cylindricality" would look like **** in a

headline, wouldn't it? On the other hand, a ball is "round"

and a circle or disc is "round," but they're... never mind.

Onward. |

||

|

|

Problems With Unsupported Tire Material. Though generally not a major problem with the more common "smaller" tires (those of appx. 1.0" diameter), unsupported tire material can prove to be a major pain in the larger, "scale" diameter sizes. Beyond the frequent hassle of fitting some of these monster meats inside and under a given body, one also occasionally encounters one or two other problems, some of which can be extremely difficult to diagnose. Ok, so they're round, mostly flat, have enough tread surface to choke a horse, and you're not skimping on the glue. Yet |

|

|

the car spins, either off the line, or 20 to 25 feet down the track. Hmm. What you could be encountering is a condition where the centrifugal force generated by the rotation of the tire is sufficient to overcome the force generated by both gravity and aerodynamic downforce. Say wha? How about this, then: it's entirely possible for tires of a certain configuration to actually lift themselves off the track. Granted, not everyone in slot car drag racing ever thought it was a good idea to run a Series with 110 gram "scale" funny cars with huge tires, a .600" tread width minimum, and open C-can motors. Some of us who did, however, after being told that no one could possibly fit those tires, with a 1.375" maximum tire-to-tire dimension, under a scale-sized body and still run a sidewinder motor, proceeded to do just that. Space-age tolerances? You betcha, including an .060" wide pinion gear. Oh yes, and some unbelievably exciting passes where the tires spun so much they actually smoked on a dry track (lift? I can't even spell litf - see?). As it turned out, the inner, unsupported tire material I had to live with - appx. .080" - was actually enough to lift that hog off the track at some point. Figure 1.5, above, shows what this might look like off the track, and suggests what the tire is trying to do on it. I discovered this only when I noted a slight bevel developing at the inner edge of the flat tread surface. Alright, so what happens when I grind the overhanging foam off? The car goes .200 faster than its best-ever pass (and almost .200 under the existing record). Duh. Solution? Very much like Figure 1.2, above, only with three angles in it, a thinned back section, and a basic "cantilever" profile that met the tread width and backspacing rule, but lacked sufficient mass and structure to lift the car. That said, are you likely to encounter the same problem? Probably not, given that not that many people run scale tires with reasonably stout motors. Could you encounter it? Perhaps. And then? While tires are by no means free, it may be worth your time to do a little careful examination, followed by some judicious trimming and/or grinding, if you run into a similar condition. The cost of experimentation is almost always less than the ultimate cost of frustration. Oh yes, they banned the sidewinder configuration in those funny car Classes for the next season, even though only one foo..., uh, competitor, bothered to build one that way. Strange, huh? |

||

|

Tire

Diameter and "Axle Steer." This not being NASCAR, having

two tires of the same diameter on a functionally "locked"

axle is reasonably critical to decent, consistent performance.

"Stagger," as our full-sized circle track brethren deal with it, is

useful both in (track) cornering performance and in minor (car)

adjustment, along with spring jacks and rates, corner weights, shocks,

sway/anti-roll bars, and camber adjustments (even on "solid" rear axles).

Depending on the differential, some of these setups can be a real

pain just to drive down the straights of an oval. Since all we have

is a straight run, anything that induces any cornering

bias or preload cannot be considered a "Good Thing." |

|

|

Consider the situation, then, when you fit two tires of differing diameters to your slot drag car. Locked to the same axle, several things can occur, depending on the degree of difference in the tires. First, the axle will have an unavoidable tendency to attempt to steer itself towards the smaller tire. Figure 1.6, above left, illustrates how the larger rolling circumference requires a longer dimension to roll out per axle revolution than the smaller one does, while both consequently attempt to pivot around a radius projected out somewhere along the axle centerline. Second, while not normally very critical, any major difference in diameter tends to impart either an induced side load to one or both of the tires, or an imbalance in the inner or outer edge contact pressure, even at rest. Third, this diameter difference, depending on the wheel diameter and tire material, could be magnified during any tire growth experienced down the track. Translation: different diameter tires can make a slot drag car do ugly ****. The good news: it usually

takes a substantive difference in diameter to create a

noticeable handling problem. What's a substantive difference? Clearly,

something more than the normal variation found in an average

pair of commercially-made drag tires. Not being privy to the

manufacturing techniques of many tire makers, I presume, rightly or

wrongly, that tire diameters are cut/ground one tire at a time, on a

piece of equipment that spins all of them at the same speed and has a

fixture with preset stop of some sort for the desired finished

diameter. The bulk tires are then paired and packaged. Given

production tolerances and the nature of tire materials, it's common to

find a diameter difference of .003" to .006" in a packaged

pair. A teensie bit of bad news: some chassis, due to the nature of their provisions for mounting motors, the angle at which the motor is mounted, and the structure/design and strength of both their motor box and front-to-rear frame rails, have a tendency to wear left (rear) tires considerably faster than rights. This becomes noticeable both in basic diameter as well as tread angle (as illustrated in Figure 1.2, above). The pragmatic approach? If you're working with a bracket or Index car, basically ignore it until something inexplicable weird starts to happen. Then simply make sure it's one of the things on your problem-solving checklist. To paraphrase a popular saying, "If it is broke, do fix it," insofar as you can, by resurfacing the tires involved. If you're running a heads-up car, don't let it happen to begin with. Your goal in this area, as in all others regarding anything that could possibly have a meaningful effect on car performance, is to get and keep things as close to perfect as practically and economically possible. That means measuring tires as accurately as possible before you install them, and remeasuring them, off the car, on a scheduled periodic basis thereafter. |

||

|

Tire Width, Tread Width,

and Contact Area. Or: Why .300" wide doesn't always mean

.300" wide, at least as far as your track surface sees it. Yes, I

know; the package says that the tires contained within are

"X" wide by "Y" diameter. What actually touches

the track, though, can vary a great deal from the specified

"section width" of those tires you just bought. |

|

|

from various manufacturers, one can come up with a pretty wide variety of true width based on the same nominal number. Easiest to measure is version "A," the standard square shoulder. Presuming the manufacturer actually got the width correct, and didn't create/encounter any of the sidewall distortion problems detailed above, what you see is pretty much what you get. Version "B" illustrates a tire that has had a radius ground on both edges. This makes it a little difficult to determine the true contact width of the tire. Out of curiosity, I've occasionally resorted to the "rolling through powder" method of finding the width, where an unloaded tire is rolled through a marking powder to produce a measurable tread width pattern. What a pain. On this type of tread shoulder, I usually just hold the tire against a contrasting background and take an approximate width with the points of a digital caliper. Some times "close enough" is close enough. Illustration "C" shows an occasionally-encountered variation, where one edge appears to be radiused and one clearly appears to be beveled. No, I can't figure out why you'd do that either, but maybe that's why I'm not in the mass-market tire manufacturing business and they are. You can approximate the actual tread width using the same methods (or lack of them) as the "B" variation. |

||

|

Axle Bore Size/Alignment Problems. You might think that something like a wheel, which ordinarily must be made on a rotational device like a lathe, would have to be a) cylindrical, b) concentric, and c) true to the centerline it were manufactured on. A vast majority are. Some, occasionally, are not. At one time or another, I've encountered problems in all of these areas, and sometimes more than one on the same wheel. Those of you who've ever worked with a lathe know that once you've established the turning center for a piece chucked or colleted in a lathe, you perform every possible operation to that piece that involves a relationship to that center before you move or remove the piece from the machine. Once you do, un- |

|

|

less

you're turning between precise centers, you've usually lost the true center you were

turning to. Every so often, however, it appears the people who make

wheels put a great deal of faith in the ability of their (presumably)

CNC equipment to hold tolerances close enough to permit accurate,

critical secondary operations. Like locating the axle bore. Some clearance is necessary (ask a machinist what it actually takes to get a true .500" dowel in a true .500" hole some time), but practically determining how much is too much is not all that hard. Tighter is generally better, providing, of course that concentricity is maintained. Then: since the wheels/tires you have now probably seem to work pretty well, you can assume, in the absence of any undiagnosed tire problems, that the current fit is acceptable. Simply remember how it feels, and look for anything that feels substantially looser when you're examining some new tires you've just purchased. Before any other operation, I do a "wiggle test" on the axle bore in the wheel, both on purchased tires and on the ones I make myself. As discussed elsewhere in this site, what you do if and when you discover something that seems excessive or improper in a product you've purchased involves the relationship between you, your track owner, the distributor, and the manufacturer, some of the above, or all of the above. In this case, despite the actual rarity of real problems, it might be best to establish with your track owner what your options are before you encounter a problem. |

||

|

|

The Effect of Wheel Diameter on Tire-to-Wheel Adhesion. While it may not be readily apparent in or out of the package, or even after a large number of runs, the size of the wheel in relationship to the size of the tire "donut" hole in which it fits has a meaningful effect on how well and for how long a tire may perform at an optimum level. True story: one of the people for whom I build and maintain various and sundry cars kept complaining about losing the wheel-to-tire bond after a rather small number of runs on each pair of a particular brand of tires. I chalked it up to an overuse |

|

|

of motor spray, bad aim, bad juju, whatever, and generally ignored the problem. After months of this same repeated condition, I finally told him to put the bad or loose tires in the next package of rusty, slimy, ******-up, hammered, beat-to-****,... ahem... next package of cars and motors he sent back for what we euphemistically refer to here at Unc's as "freshening" (aka: "total, ground-up rebuild"). Sure enough, in the next Care Package was a bag of approximate 50 pair of tires. I opened it, thinking, "Gee, how bad can this be?" and picked a tire at random. I pressed gently on the hub to see how bad the debonding was, and the wheel popped out and fell on the floor. Oh. Uh, ok, maybe he has a point here. After some examination (push, plop, push, plop, etc.), it turned out that the manufacturer had simply used a wheel with an o.d. (outside diameter) almost exactly the same size as the i.d. (inside diameter) of the raw tire "donut," as illustrated by wheel "A" in Figure 1.9, above left. So? So turning ninety gazillion rpm, I believe you want as much additional clamping force holding that tire to that wheel as you can get. A simple, almost "slip fit" means that all the adhesion between those two dissimilar components has to be achieved by what is, in essence, a contact cement joint between metal and rubber or foam. Woo woo. That's asking a lot for what's basically a thinned variant of RTV, no matter what exotic name/claim the cement manufacturer attaches to it. Given the choice, most manufacturers opt for the "B" fit; significantly tighter, more externalized "clamping" force, and a much bigger pain to assemble quickly and correctly. How can you tell what fit your wheels/tires actually have? Absent soaking the tire off the wheels (or blowing them off on a run), you can't, at least while they're still assembled. A periodic inspection of that inner and outer bonding area would probably be in order, however, no matter what the assembly fit is. If, by a slight sideways distortion of the tire, you note a visible gap between the tire and the wheel, you've got a/the problem. While not a long-term solution, a quick but judicious application of a dab or two of super glue at that joint will probably get you a round or two on the tire(s) in an absolute emergency. |

||

|

"Spare the Glue, Spoil the Tire." While we're talking about tire-to-wheel adhesion here, let me point out that it's possible to come across tires where the manufacturer has been, to be polite, less than generous with the actual coverage of the cement in that critical wheel/tire joint. Foolish person that I am, I figure 100% coverage is still a little iffy when you confront the possibility of easily spinning the sucker at something approaching 30,000 rpm. Imagine my surprise and relief, then, to run across several new pair of tires where the manufacturer had reduced that coverage to a thin bead of cement that sort of ambled around, gosh, almost 90% of the circumference of the tire. Silly me, wasting all that cement (twice!) and worrying about full coverage. This little technique came to light while I was examining some tires a friend had purchased, and just after he said "And why are you bending the sidewalls like that?" Bet that set would have been good for a bunch of solid passes, huh? |

||

|

What About Tire

Balance? First, some basic questions and answers about balance and

slot car drag racing tires. Is there some performance or advantage to

be found in well-balanced tires? Yes. Is it practically achievable by

the average racer? Sort of. Is it, ultimately worth the time and

effort? Usually not, with some specific exceptions. I am absolutely not smart enough, nor nearly patient enough, to attempt this process on an undrilled wheel; I used to work for people who made extremely high-precision crankshaft balancers, and the very thought of calculating the precise location and exact weight of the material removed by drill or mill in the sub-fractional sizes necessary makes me fuzzy just to think about, much less attempt. However, as to the drilled variety... |

||

|

|

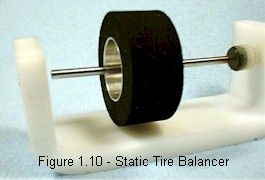

Figure 1.10, at left, is a photo of a commercial static balancing device I

occasionally use, shown with a 1.200" diameter, large hub,

"scale" tire in the process of being "balanced."

This device indicates four relative balance conditions, which I can

describe using the following precise technical terms: 1) "Really

****** up," 2) "Sort of bad," 3) "Sort of

o.k.," and 4) "This is boring and it's close enough." |

|

|

seem to respond better to the effort.

Personally, they're they only tires I even think about balancing, much

less go through the pain of actually doing. I spent some time working

with smaller sizes (basically, the generic, natural rubber .300"

x 1.000" tire) and could find no improvement in e.t. (or speed,

for that matter) that fell outside of normal statistical variations.

Should you elect to pursue the relationship of balance and performance

improvement, at least with smaller tires, your results may be

radically different. Have at it. At this point, given the amount of

time available to devote to practical and demonstrable areas of

performance improvement, I don't bother. I will, however, pay very

close attention if and when some enterprising individual or company

introduces a reasonably-affordable, accurate, dynamic slot car

tire balancing device. I'm not holding my breath on this one, and you

probably shouldn't either. |

||

| So - What does it all mean? | ||

|

Here's a number you

should keep in mind when thinking about tires: 210. No matter how well

or how badly that wowie-zowie body is working, no matter how

efficiently your chassis is performing, despite your motor's capacity

to turn nine gajillion rpm and pull stumps, exclusive of tire spin and

growth, a 1.000" tire will revolve no more than about 210

times in the course of a 55-foot pass, a 1.200" tire no more than

appx. 175 times, and a .960 tire appx. 219 times. Period. Any tire

growth makes those numbers smaller, not larger. |

||

|

|

||

|

all contents © 2000 UFIE - f_eubel@juno.com |

||