The Standard

I found the standard of the engine quite difficult to machine. It had few edges to reference from and the smallest wrong angle on any of the sides would give a skewed looking engine. All the surfaces were critical with this component to ensure it was upright across 2 axis and the top and front faces needed to be perpendicular.

I started by bolting the standard to the cross slide and fly cutting the base. The set-up was most important here to ensure that the final component would stand squarely on the sole plate.

Fly cutting the base of the standard

Next I machined the front face which would need to be perpendicular with the base just cut. I achieved this by bolting an angle plate to the cross slide and squaring it up. Then I clamped the base of the standard to this angle plate. For extra support I added my vertical slide with a vice mounted on it. In this set-up I then fly cut the front face.

Machining the front face.

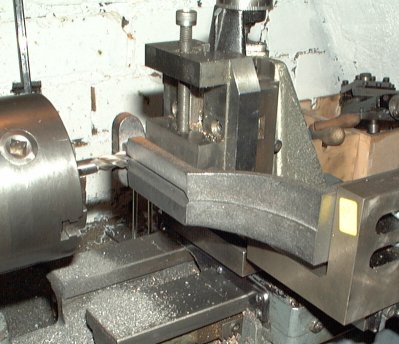

To cut the slot in the front face I removed the clamps on the angle plate and moved the component vertically (using the vertical slide) until the centre line was in line with the centre of the lathe. Then I re-clamped the angle plate clamps and cut the slot using the cross slide.

Machining the slot in the standard.

I found that there wasn't enough metal to cut the slot to it's full depth of 1/8th ". So I cut as deep as I could and would therefore need to make the cross-head accordingly.

To cut the top face I removed the angle plate completely and used the side of the cutter and the movement of the vertical slide to cut the standard to it's final length. (Remembering to remove an extra 1mm to compensate for my lower cylinder cover change)

Machining the top face of the standard

The drilling of the standard was just done with careful marking and using the drill press.

** UPDATE **

After finding the top face of the standard to be sloping in the

Assembly Check No 1. I decided to re-machine it. On reflection this is probably a better way to machine it in the first place so here is the set-up I used. It was simply an angle plate bolted to the cross slide and squared up. Then I clamped the standard to it ensuring that the lower face was vertically perpendicular to the lathe bed. Then I fly cut the top face square.

Re-machining the top face of the standard

Back to Contents