As a scientific term work involves movement and force. If you exert force and no movement occurs, scientifically, you have not done work. Work is calculated scientifically by the following formula: W = F X D (work equals force times distance). The SI (metric) unit for force is the newton, and the SI unit for distance is the meter. The SI unit for work is the newton/meter, which is also known as the joule. One joule is the work done by a force of one newton that moves an object a distance of one meter. Larger units of work are the kilojoule (kJ) which is equal to 1,000 joules, and the megajoule (mJ) which is equal to a million joules. Anything that changes the size or direction of forces used in doing work is called a machine. A machine can be an inclined plane, such as a ramp used to slide a heavy object on to a truck. A ramp allows you to use less force to lift an object, so it is a machine. In exchange for using less force, you have to move the object a longer distance. See figure 5.5, page 201. If you take an inclined road up a mountain, it requires less force than going straight up the mountain, however, you must travel a greater distance.

When a machine reduces the force used to move an object it give a mechanical advantage (M.A.). If a machine has a mechanical advantage of 1, there is no change in the force you have to apply. If the M.A. is 2, it allows you to apply only half the force needed to move an object without the machine. An M.A. of three, allows you to use only one third the force to move the object.

The work put into a machine is called work input. The work done by the machine is called work output. Work input is always greater than work output because of friction. The efficiency of a machine is calculated by dividing the work output by the work input. If it were not for friction, efficiency could be 100%. However, because of friction, it is always less than 100%. A machine may allow you to do work that you could not do without the machine, by reducing the force necessary to create movement. However, the movement is always greater. You could not carry a 1,000 pound weight for a distance of 100 meters. You could, however, carry 200 50 pound weights. But you would have to travel a longer distance, and therefore, there would be more friction. This illustrates the principle of efficiency always being less than 100%. Anything which reduces friction, such as lubricants, will improve efficiency.

A wedge is an inclined plane which is thick at one end and thin at the other. The force exerted on the thick end is concentrated at the thin end. The result is more force applied to a very small area. This is why a wedge is used to split things, such as wood. An ax, a knife and a razor blade are all wedges.

A screw is another form of inclined plane. It is an inclined plane which twists. You must turn a screw a great distance to get it to penetrate a small distance. But because its edge is sharp, it exerts force to a small area.

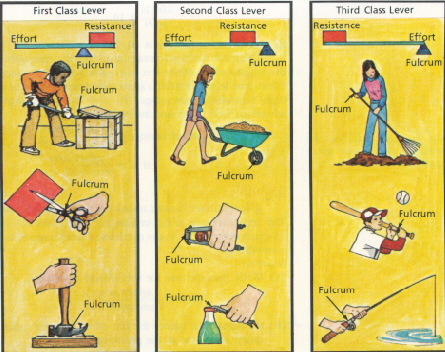

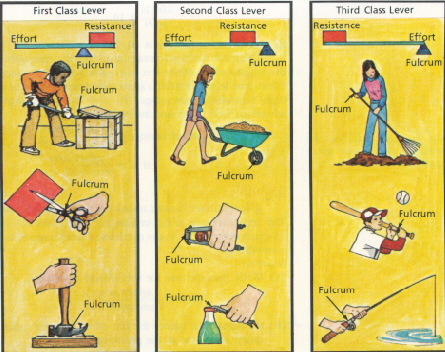

A crowbar, a wheelbarrow and a rake are all machines. All of them have a point that is moved by a force, and a part that does not move called a fulcrum. Machines that do work by moving around a fulcrum are called levers. The force applied to the lever is called the effort force. The weight of the object being lifted is called the resistance force. The length of the lever between the fulcrum and the resistance force is called the resistance arm. The length of the lever from the fulcrum to where the effort force is applied is the effort arm. The M.A. of a lever is calculated by dividing the length of the effort arm by the length of the resistance arm.

There are three general types of levers. With a first class lever, the fulcrum is always between the two forces. A first class lever changes the direction of a force. An example of a first class lever is a crowbar. For a second class lever, the fulcrum is at the end of the lever, the resistance force is near the center, and the effort force is applied to the other end. A wheelbarrow is an example of a second class lever. Unlike the first class lever, the direction of the force is not changed. See figure 5-11, page 207. In a third class lever the fulcrum is always at one end, the resistance force is at the other end, and the effort force is applied in between the fulcrum and the resistance force. A rake is an example of a third class lever. Your hand at the end of the rake is the fulcrum. The leaves of the rake which scrape the ground is the resistance force. Your other hand in the middle of the rake handle applies the effort force. All third class levers are used to increase the distance moved, not to decrease the force applied.

Inclined planes and levers are simple machines. A compound machine is a machine made up of two or more simple machines. Since a wheelbarrow uses both a lever and a wheel, it is a compound machine. Another simple machine is the pulley. A pulley is actually a type of lever. See figure 5-13, page 210. A combination of pulleys is called a block and tackle. A block and tackle can be used to obtain a large mechanical advantage to lift heavy objects, such as a piano or an automobile engine.

Power is how fast work is being done. Power is the rate at

which the work is done. It is equal to the work done divided by

the time required to do the work. The answer is given in joule per

second. Another name for joules per second is the watt (w).