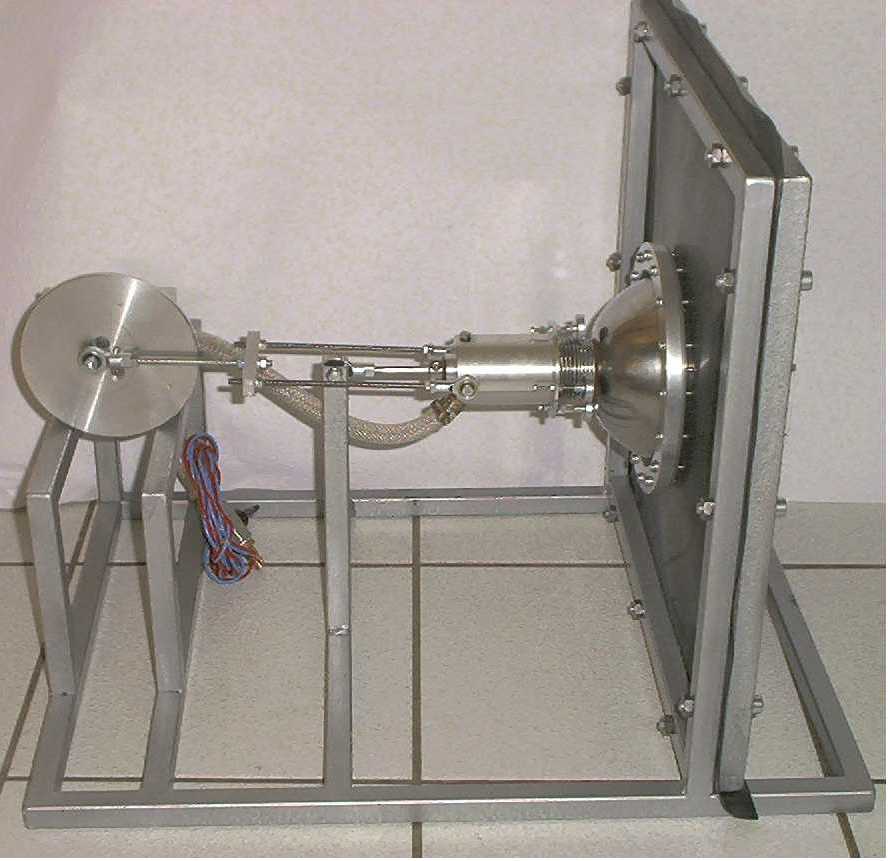

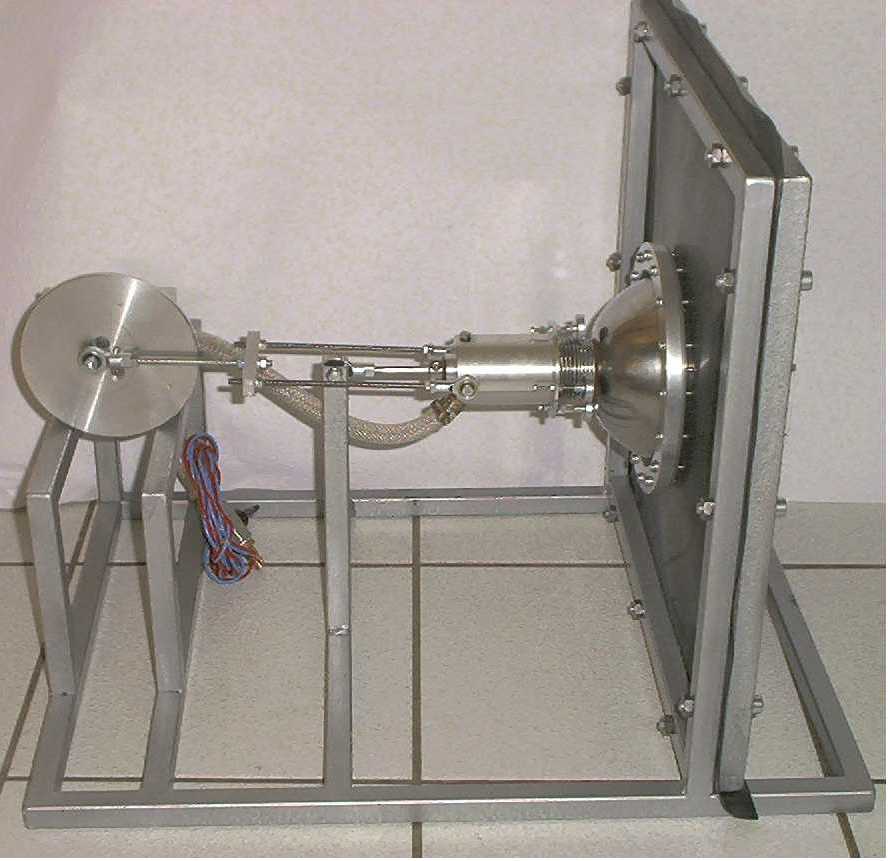

Here is the first prototype using the MC technology for a cooling

Stirling cycle.

Behind the flywheel there is a 40W DC electric engine.

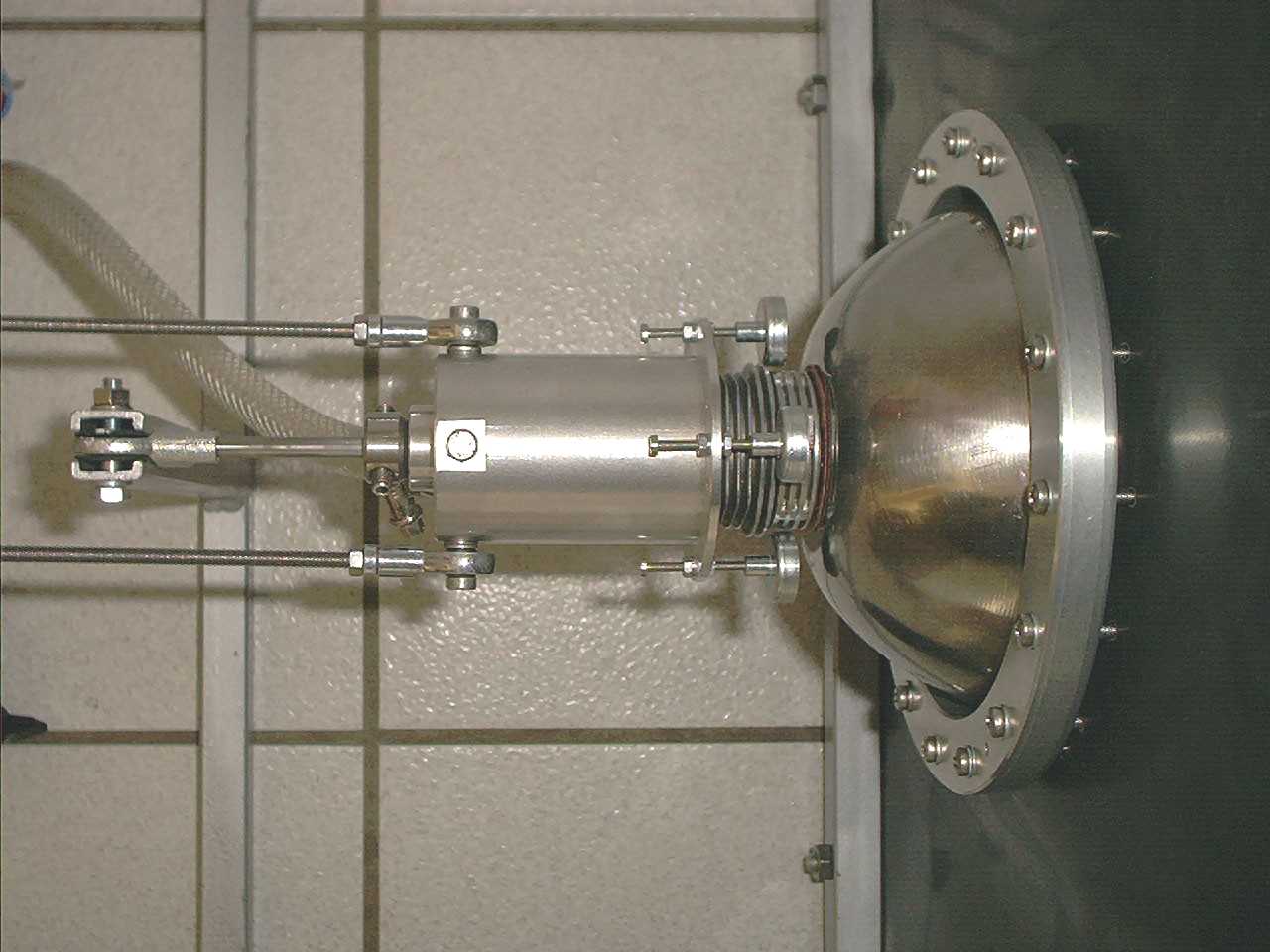

The expansion volume is 15cc, with a 26mm stroke.

In the above configuration:

- the displacer stroke is about 2mm only

- the swept volume (by the displacer) is about 45cc

So the displacer inside is almost about the near-ball-shape

cylinder you see, having its regenerator annular inside.

Behind the piston is an about 80cc buffer chamber, which is

airtight to the rod, leading out to be fixed at the frame.

The buffer chamber was made to be able to charge the engine, while

not getting gas losses through the piston rings.

The big black foil you see (fixed to the metall frame)

is just made of rubber and :

- acts as a curtain between the cold and the warmer cylinder parts

- leads inside the cylinder and is the sealing for the displacer

- acts as a kind of bearing for the cylinder, when moving

In a detailed view you see the magnets (close to the cylinders cooling fins.

They fix the displacer up to the very last moment to pop of to the

other side while expanding. At the cold end of the engine, you see

a screw, on which usually (for testruns) there are mounted the other four

magnets (for a reziprocal behavior at compression). But they are dismounted

now !

Detailed top view

Seen from the front